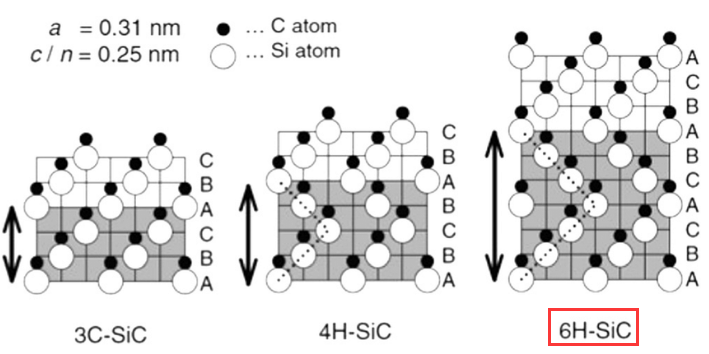

PAM-XIAMEN can offer 6H SiC wafer with n type or semi-insulating. Silicon carbide wafer is a material presenting different crystalline structures called polytypes, which has more than 250 structures. Different polytypes has different atomic stacking sequences. Polytypes generate the cubic, hexagonal or rhombohedral structures, which include 50% C atoms bonded with 50% Si atoms. Nevertheless, only hexagonal structures of 4H-SiC and 6H-SiC and the cubic structure of 3C-SiC can be for commercial use. Here we make a brief introduction as follows:

1. Specifiaction of 2” 6H SiC Wafer

| SILICONE CARBIDE WAFER 50.8MM (2”) 6H, N type | |

| Surface orientation | (0001), Si side |

| Off-orientation | (0,0 ± 0,5)° |

| Diameter | (50,8 ± 0,38) mm |

| Nominal thickness | (330 ± 25) um |

| Thickness tolerance (TTV) | ≤ 10 um |

| MPD | ≤15/cm3 |

| Bow | ≤ 10 um |

| Warp | ≤ 25 um |

| Roughness of front and back sides | Ra < 0,5 nm |

| Primary flat | Yes |

| Primary flat orientation | (11-20) ± 5° |

| Primary flat length | (16 ± 1.65) mm |

| Additional flat | Yes |

| Additional flat length | (8 ± 1.65) mm |

| Chamfer | Yes |

| Package | individual or multi-unit package EPAK type,

vacuum packing |

| Additional flat is turned through (90 ± 5)° in reference to the primary flat c.w. (from the front side) | |

2. 6H SiC Crystal Structure

The SiC 6H structure is a hexagonal wurtzite crystal structure. It refers to a stacking sequence of AαBβCγAαCγBβ, which is composed of 2/3 cubic bonds and 1/3 hexagonal bonds, and the C atoms relative to location of Si atoms are fixed. The figure is shown below:

3. Basic Parameters of 6H SiC

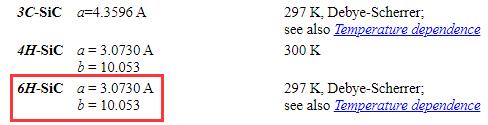

1) 6H-SiC Lattice Constant, please see the highlight part:

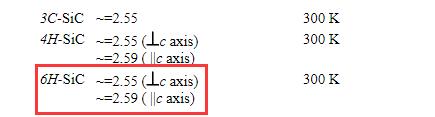

2) Infrared refractive index of 6H-SiC, please see the highlight part:

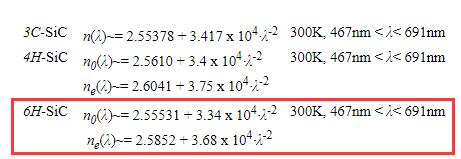

3) Refractive index n(λ), please see the highlight part:

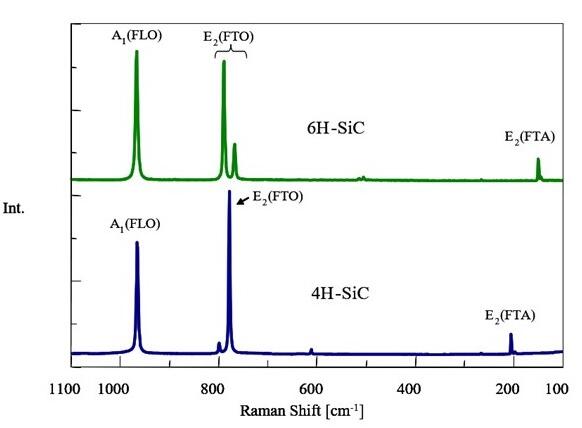

4) Comparison of 6H-SiC Raman Spectra and 4H-SiC Raman Spectra

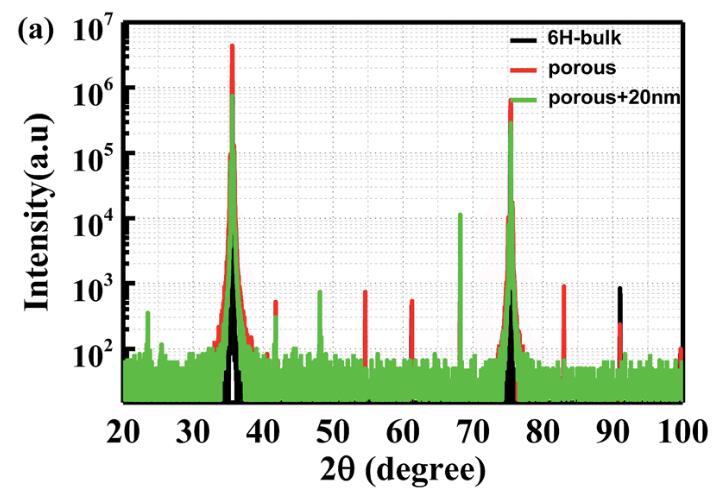

5) 6H-SiC XRD Diagram

4. Similarities Among the Polytypes of 6H-SiC, 4H-SiC and 3C-SiC in Applications

Although different polytypes have different properties, there are similarities in tendency. The silicon carbide breakdown field is 2-4 MV/cm, and the silicon carbide energy bandgap is 2.3-3.2eV, which are higher than that of silicon. Therefore, silicon carbide is a wide bandgap material. Combing the two properties makes a great superiority for electrical equipments with a low on resistance and low leakage current. Moreover, the saturated electron velocity of SiC material is high. It is a very important parameter for high frequency application. Besides, the thermal conductivity of silicon carbide is about 3 times higher than silicon, which is beneficial for high temperature devices. This property has an advantage over the wide bandgap material(like GaN). And silicon carbide substrates can be used to grow graphene layers by thermal decomposition under ultra-high vacuum conditions.

5. Difference Between 4H and 6H SiC Wafer

1)Commercial resistivity of 6H n type SiC Wafer is (0.02~0.1)ohm.cm, while 4H one is (0.015~0.028)ohm.cm.

2)Stacking sequence of 6H SiC substrate is ABCACB, while 4H one is ABCB

3) Semi-insulating 6H SiC thermal conductivity is a~460W/mK and c~320W/mk, while 4H one is a~490W/mK and c~390W/mK. For n type SiC, its thermal conductivity, take 4H one as an example, a~420W/mK and c~370W/mK, which is much lower than semi-insulating one, what is why end user choose Semi-insulating SiC as heat sink or other conductivity material.

4)6H-SiC band gap is 3.02eV while 4H one is 3.23eV.

5)Hole Mobility of 6H SiC substrate is 90cm2/V.s while 4H one is~115cm2/V.s

6)Electron mobility of 6H SiC wafer is ~400cm2/V.s while 4H one is ~800cm2/V.s

6. FAQ about 6H-SiC Wafer

Q1: If the Thermal Conductivity of SiC-4H N-type is 420 W/mK -What is the Thermal Conductivity of your SiC-6H N-type material ?

A: Theoretically it is the same between 6H and 4H.

Q2: I am curious about this because one of the reviewer of my paper wants to know the surface roughness before CMP. Could you tell me the surface roughness of the original 6H-SiC wafer before CMP processed?

A: The surface roughness of 6H-SiC wafer is <1nm before CMP after mechanical polishing.

For more information, please contact us email at victorchan@powerwaywafer.com and powerwaymaterial@gmail.com.