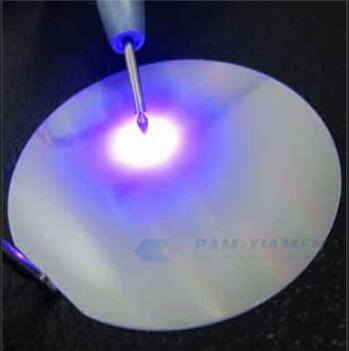

AlGaN is a direct wide band gap semiconductor material. By changing the composition of AlGaN material, the band gap size can be continuously adjusted from 3.39 eV to 6.1 eV, covering the UV band range from 210 nm to 360 nm, so it is an ideal material for the preparation of UV LED. Therein, AlGaN UV LED uses are covered in many fields such as sterilization, environmental purification, anti-counterfeiting identification, and biochemical detection. PAM-XIAMEN can provide UV LED wafers, including AlGaN LED wafer, for fabricating ultraviolet light emitting devices. The AlGaN LED wafer listed below is grown with 10% Al composition. We also can epitaxially grow AlGaN LED structure with high Al composition, for specific information please contact sales team victorchan@powerwaywafer.com.

1. Epitaxial Structure for AlGaN UV LED Array Fabrication

PAMP17168-ALGAN

| Epi Layer | Thickness | Doping Concentration |

| pGaN | 10nm | heavily doped |

| p-AlGaN (10% Al) | – | heavily doped |

| p-GaN | – | lightly doped, p=5E16-1E17 cm-3 |

| undoped well/ barrier | – | |

| n-GaN | 50nm | – |

| n-AlGaN (10% Al) | – | heavily doped |

| n-AlGaN or n-GaN (Al composition<10%) | 1.7-3 um | heavily doped |

| undoped | – | |

| sapphire substrate |

AlGaN is the main material of AlGaN ultraviolet micro-LEDs, and different Al compositions have an impact on the luminescence wavelength of the devices. Therefore, the determination of Al composition in AlGaN is very important. Generally speaking, if AlGaN material is not strained in the epitaxial layer, the Al content is the only factor affecting the lattice constant.

The shorter the AlGaN UV LED wavelength, the higher the Al composition required. However, with the increase of Al content, the challenges of growth, P-type doping, ohmic contact fabrication and other aspects of the material will increase. The AlGaN UV LED efficiency is always limited, and decreases sharply with the increase of Al composition. Take the P-type doping for example.

2. P-Type Doping Research Progress of AlGaN Ultraviolet LED Epitaxy

With the improvement of epitaxial AlGaN UV LED technology, the crystal quality of AIGaN with high Al composition has been greatly improved, and the background electron concentration has become lower and lower. However, regardless of N-type or P-type doping, with the increase of Al composition, the conductivity of the epitaxial layer drops sharply, especially for P-type AlGaN materials. This is because the activation energy of Mg acceptor in AIGaN linearly increases with the increase of Al content, so it is difficult to increase the hole concentration by only increasing the doping concentration of Mg. In this way, the concentration of P-type AlGaN hole is far less than that of N-type AlGaN electron. As a result, there is a large amount of electron surplus when the electron hole pair performs composite luminescence, and the hole injection efficiency is low, which leads to electron leakage in the injected active region.

In order to improve the hole concentration, many doping techniques have been developed, such as δ doping, co-doping, polarimetric induced doping, superlattice doping and quantum engineering non-equilibrium doping etc. The results show that δ doping of Mg improves the P-type conductivity by introducing local band modulation and reducing the scattering of impurities. In co-doping technology, a certain amount of donor impurities, such as Si or C, is added to reduce the activation energy of acceptor. Polarization-induced doping is to use gradual Al compositions to form a polarization field in the material and then induce the acceptor to activate. Superlattice doping makes use of valence band order and polarization field to violently bend its energy band and form periodic oscillations, thus reducing the acceptor activation energy in some molecular layers and increasing the activation rate. These methods have indeed achieved certain effects on Ga-rich AIGaN materials. However, due to various factors, these methods have not made much progress in high Al composition AlGaN UV LEDs.

As for quantum engineering non-equilibrium doping methods, the method introduces GaN quantum structure into AlGaN material system, and the dopant is doped in the matrix material near GaN local quantum structure, the non-equilibrium material system is formed, prompting system to the top of valence band (VBM), and to ensure that the impurity can effectively release hole to VBM, As a result, the activation energy of AlGaN acceptor, thereby improving the performance of UV LED devices.

Remark:

The Chinese government has announced new limits on the exportation of Gallium materials (such as GaAs, GaN, Ga2O3, GaP, InGaAs, and GaSb) and Germanium materials used to make semiconductor chips. Starting from August 1, 2023, exporting these materials is only allowed if we obtains a license from the Chinese Ministry of Commerce. Hope for your understanding and cooperation!

For more information, please contact us email at victorchan@powerwaywafer.com and powerwaymaterial@gmail.com.