PAM XIAMEN offers Borosilicate Float Glass from SCHOTT. We have a large selection of Schott Borofloat 33 glass wafers in all sizes. We have borofloat glass as thin as 100 microns. Borofloat 33 is the sanme as Pyrex 7740 and has the same anondic bonding properties. Diameters range from smalled diced pieces up to 12 inches. More details please see the following Borosilicate Lid specifications:

1. Specifications of Borosilicate Wafer

Borosilicate Lid 6″ 0.12±0.01mm / Both Side Polishing

Borosilicate Lid 6″ 0.13±0.01mm / Both Side Polishing

Borosilicate Lid [6″ 0.115mm] Tolerance ±0.01 / Both Side Polishing

Borosilicate Lid [6″ 0.2mm] Tolerance ±0.01 / Both Side Polishing

Borosilicate Lid [6″ 0.22mm] Tolerance ±0.01 / Both Side Polishing

Borosilicate Lid [6″ 0.28mm] Tolerance ±0.01 / Both Side Polishing

Borosilicate Lid [6″ 0.33mm] Tolerance ±0.01 / Both Side Polishing

For borofloat 33 refractive index, table below is for your reference:

| Wavelength | Refractive index(n) |

| 435.8 | 1.48015 |

| 479.9 | 1.47676(nf) |

| 546.1 | 1.47311(ne) |

| 589.3 | 1.47133 |

| 643.8 | 1.46953(nc) |

| 656.3 | 1.46916 |

2. Borofloat 33 Mechanical Properties

BOROFLOAT® 33 is a high quality boro-silicate glass with outstanding properties for a wide-range of applications.

This unique special float glass is manufactured by SCHOTT JENAer GLAS using the Microfloat process and the latest technology. This technology also results in a homogeneous material that has an excellent mirror-like surface, a high degree of flatness and an outstanding optical quality.

BOROFLOAT® 33 is a clear and transparent colourless glass. Its excellent trans-mission and its very weak fluorescence intensities over the entire light spectrum make BOROFLOAT® 33 ideal for a wide range of applications in optics, optoelec-tronics, photonics and analytical equip-ment.

Its low thermal expansion, its high thermal shock resistance and its ability to withstand temperatures up to 450°C for long periods make BOROFLOAT® 33 a good choice for applications which call for good temperature stability (e.g. internal panels in pyrolytic self-cleaning ovens and over plates for high-power floodlights).

BOROFLOAT® 33 is highly resistant to attack by water, strong acids, alkalis as well as organic substances. Therefore it is particularly suitable for applications in the chemical industry such as sight glas-ses for reaction vessels and fittings.

Another interesting field of application is in medical and analytical technology. Measurements are hardly influenced by the glass receptacle because the expo-sure to water and acids results only in the leaching out of small amounts of ions from the glass.

For borofloat 33 density, it is lower than soda lime float glass. It makes it possible to construct lightweight lamina-ted glass systems (e.g. bulletproof glass).

Borosilicate glass from SCHOTT has proven itself in many traditional applications and, today, there is an increasing area of usage in new and technically sophisticated special glass applications such as biotechnology, microelectronics and photovoltaics.

3. Uses of Borosilicate 33

- Home Appliances (interior oven doors, fittings in microwave appliances, window panels for fireplaces)

- Environmental engineering, chemical industry (resistant linings and sight glasses for reaction vessels, microfluidic systems)

- Lighting (protective panels for spotlights and high-power floodlights)

- Photovoltaics (glass for solar collectors)

- Precision engineering, optics (optical filters and mirrors etc.)

- Medical technology, biotechnology (slides, biochips, titration plates, DNA sequencers, microfluidic systems)

- Semiconductor engineering, electronics, sensors (wafers, display glass)

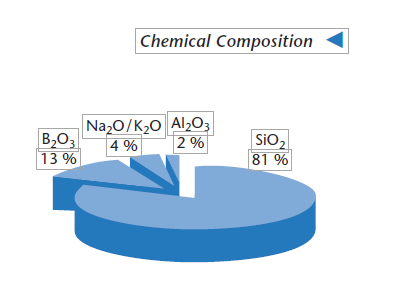

4. Borofloat 33 Composition

The compositions of BF33 wafer is shown as the diagram below:

For more information, please contact us email at victorchan@powerwaywafer.com and powerwaymaterial@gmail.com.