Photomask blank with antireflective chromium is available. Photomasks are mainly used in integrated circuits, flat panel displays (including LCD, LED, OLED), printed circuit boards and other fields. The photomask is a pattern master used in the photolithography process in microelectronics manufacturing. Here are specifications of photo mask blank for your reference:

No. 1 Photo Masks PAM190302-MASKH

No. 1-1 Silicon wafers with IC structures (ASIC11) at 0.35 micron design standards;

No.1-2 Silicon wafers with IC structures (ASIC12) at 0.35 micron design standards;

Note:

The diameter of the substrate >= 150mm. the type / doping admixture, orientation, thickness, resistivity, front surface, rear surface, flat (s) is determined by the manufacturer to provide the required element base parameters (transistors, resistors, capacitors) specified in the Design Kit. The manufacturer provides a Design Kit suitable for IC topology development. The customer performs the development in accordance with the Design Kit and transmits the information to the manufacturer in GDS format. The manufacturer produces a set of photomasks in accordance with the information in the GDS format. The manufacturer manufactures the plates using a set of photomasks and according to the Design Kit requirement.

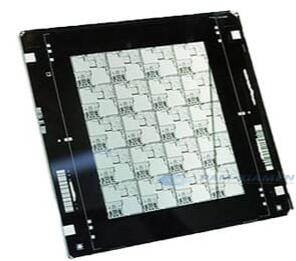

No. 1-3 Photomask Blank

size 152 x 152 x mm, scale 5: 1, designed for photolithography with design standards of 0.35 μm;

Basic Template Requirements

Purpose: binary templates for projection f / l

Substrate size: 6 “x6” x0.25 “, quartz

Equipment type: 5x, NIKON NSR 2205i11D

Exposure field: 110 mm x 110 mm

Pellicle: Yes, NIK49P-122-1K17 / HFLC, one-side protection from chrome (two-way protection on demand)

Minimum critical size: 1.75 microns

Reproducibility of critical dimensions: 0.05 µm (3σ)

Registration Accuracy (Registration): 0.1 µm

Defect: 0.1 / cm2 (1 micron)

No. 2 Chromium Photomask on Quartz PAM200313-MASKH

No. 2-1 Least complex one: Strip & Ship;

CD >= 5um;

Vast open areas; Write Grid: Standard

Material: quartz, antireflective chromium. No pellicle.

No. 2-2 Moderate one:

5x reticle; 6”x6”x0.12” Quartz;

No defects bigger than 2,5um;

Smaller than 1,25um defect

CD >= 5um; lines/spaces/octagons;

Write Grid: Should maintain CD

Material: quartz, antireflective chromium. No pellicle.

No. 2-3 Most complex one:

5x reticle; 6”x6”x0.12” Quartz;

No defects bigger than 1,25um;

Smaller than 0,625um defect

CD >= 2,5um; lines/spaces/ octagons;

Write Grid: Should maintain CD

Material: quartz, antireflective chromium. No pellicle.

There won’t be any pellicle necessary in these photomask blanks, and the reticle mask size will be 6” x 6” and 0.12” in thickness. Min feature sizes on masks are 2,5um and 5um. Photomask (reticle) is for fabrication of the lithography process to be used in stepper machines.

The technical parameters of photomask blank meet the requirement in Table 1 and Table 2.

|

Table 1 Photo Mask Quality Level Parameters |

||||||||||||||||

| Grade | D | C | B | A | S | T | U | V | W | W+P | X | X+P | Y | Y+P | Z | Z+P |

| Tolerance | ±0.3 | ±0.3 | ±0.2 | ±0.15 | ±0.1 | ±0.1 | ±0.05 | ±0.04 | ±0.035 | ±0.035 | ±0.032 | ±0.032 | ±0.028 | ±0.028 | ±0.022 | ±0.022 |

| Mean to target | ±0.3 | ±0.3 | ±0.2 | ±0.15 | ±0.1 | ±0.075 | ±0.05 | ±0.04 | ±0.03 | ±0.03 | ±0.028 | ±0.028 | ±0.025 | ±0.025 | ±0.02 | ±0.02 |

| Uniformity | 0.2 | 0.2 | 0.2 | 0.15 | 0.1 | 0.075 | 0.05 | 0.04 | 0.035 | 0.035 | 0.035 | 0.035 | 0.03 | 0.03 | 0.025 | 0.025 |

| Registration | ±0.4 | ±0.3 | ±0.2 | ±0.15 | ±0.1 | ±0.075 | ±0.05 | ±0.06 | ±0.055 | ±0.055 | ±0.05 | ±0.05 | ±0.045 | ±0.045 | ±0.04 | ±0.04 |

| Defect size | 1.5 | 1.5 | 1 | 0.8 | 0.6 | 0.4 | 0.4 | 0.35 | 0.3 | 0.3 | 0.25 | 0.25 | 0.2 | 0.2 | 0.2 | 0.2 |

| Defect density | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Edge defect | / | / | / | / | / | / | / | 0.3 | 0.3 | 0.3 | 0.25 | 0.25 | 0.2 | 0.2 | 0.2 | 0.2 |

| Edge roughness | / | / | / | / | / | / | / | 0.3 | 0.3 | 0.3 | 0.25 | 0.25 | 0.2 | 0.2 | 0.2 | 0.2 |

| Corner rounding | / | / | / | / | / | / | / | 0.3 | 0.3 | 0.3 | 0.25 | 0.25 | 0.2 | 0.2 | 0.2 | 0.2 |

| PSM phase | / | / | / | / | / | / | / | / | / | 180±4 | / | 180±3 | / | 180±3 | / | 180±3 |

| PSM trans | / | / | / | / | / | / | / | / | / | 6±0.4 | / | 6±0.3 | / | 6±0.3 | / | 6±0.3 |

Note:

The parameters are applicable to scale reticle; the quality level is ranked from low to high:

- 0.5um process supports up to S level; 0.35um process supports up to U level, 0.18um process supports up to X level;

- Ordinary glass mask is only applicable to Class D.

| Table 2 Requirements for Photomask Quality | ||||||||

| 1:1 Main Mask | 1:1 Electron Beam Scanning | UT mask | ||||||

| Grade | PB | PA | EB | EA | ES | uc | UB | UA |

| CD spec | >2.5 | 1.2~2.5 | >1.5 | 1.2~1.5 | <1.2 | >2 | 1.5~2.0 | <1.5 |

| Tolerance | ±0.25 | ±0.2 | ±0.2 | ±0.15 | ±0.1 | ±0.25 | ±0.2 | ±0.15 |

| Uniformity | 0.3 | 0.3 | 0.3 | 0.25 | 0.2 | 0.25 | 0.2 | 0.15 |

| Registration | ±0.8 | ±0.8 | ±0.2 | ±0.15 | ±0.1 | ±0.2 | ±0.15 | ±0.1 |

| Defect size | 2 | 2 | 1.5 | 1.5 | 1.0 | 2 | 1.5 | 1 |

| Defect density(pcs/in2) | 2 | 1 | 2 | 1 | 0.5 | 0 | 0 | 0 |

Note:

The requirement is applicable to 1:1 mask, and the quality level is ranked from low to high;

UT mask is only applicable to quartz material; ordinary glass mask is applicable to the highest level B.

No.3 Photolithography Blank PAM200326-MASKH

Glass substrate:

Size: 50x50mm +/-0.2mm;

Thickness: 3.67mm +/-0.02mm

Material: QUARTZ

No Spec. on Flatness: 1/4 ~ 1/2 wavelength

Free of chip on edges

Starting substrate 7X7inch X 150mil

Standard reticle blank Coating 3.0 OD AR Chrome

No. 4 Photo Mask on Quartz PAM200602-MASKH

No. 4-1 Photo mask

Mask size 5” X5”

MASK SUBSTRATE MATERIALS: Quartz

Lithography: electron beam

Mask polarity: BF

Feature tolerance: 0.02um

Feature size: 0.4um

Accuracy: 0.12 um

Manufacturing Grid: 0.005um, 0.02um

No. 4-2 Photomask Blank

Mask size 5” X5”

MASK SUBSTRATE MATERIALS Quartz

Lithography: laser

Mask polarity: DF

Feature tolerance: 0.5um

Feature size: 10 um, 3um, or 5um

Accuracy: 0.12 um

Manufacturing Grid: 0.02um

No. 5 Quartz with LR Chrome PAM200811-MASKH

Mask size= 5″x 5″x 0.09″

Material = Quartz with LR Chrome

Orientation: RR Down.

Data Dark .

Critical Dimension (CD): 4 µm +/- 0.5 µm (for all masks)

Defects: 0 > 5 µm

Please note:

The Quartz with LR Chrome is for fabricating Mask Aligner (NUV Photo lithography 350-450 nm wavelength);

Data to mask scaling is 1:01 because mask aligner have scaling 1:1, instead of 5:1;

Mask material is Quartz with LR Chrome, and Chrome side is facing down (Real Read (RR) down);

In layout designing, Metal layer number 28 is used, and the area of metal layer in the design layouts should be chrome on the photo mask.

For more information, please contact us email at victorchan@powerwaywafer.com and powerwaymaterial@gmail.com.