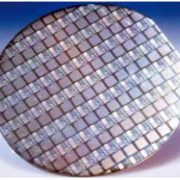

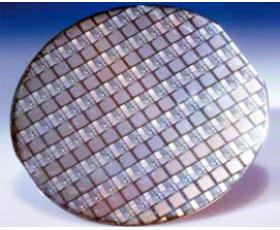

GaAs (Gallium-Arsenid) -Wafer

As a leading GaAs substrate supplier, PAM-XIAMEN manufactures Epi-ready GaAs(Gallium Arsenide) Wafer Substrate including semi-conducting n type, semi-conductor C doped and p type with prime grade and dummy grade. The GaAs substrate resistivity depends on dopants, Si doped or Zn doped is (0.001~0.009) ohm.cm, C doped one is >=1E7 ohm.cm. The GaAs wafer crystal orientation should be (100) and (111). For (100) orientation, it can be 2°/6°/15° off. The EPD of GaAs wafer normally is <5000/cm2 for LED or <500/cm2 for LD or microelectronics.

- Beschreibung

Produktbeschreibung

(Galliumarsenidinfrared) GaAs Wafer

PAM-XIAMEN develops and manufactures compound semiconductor substrates-gallium arsenide crystal and wafer. We has used advanced crystal growth technology, vertical gradient freeze(VGF) and GaAs wafer manufacturing process, established a production line from crystal growth, cutting, grinding to polishing processing and built a 100-class clean room for GaAs wafer cleaning and packaging. Our GaAs wafers include 2~6 inch ingot/wafers for LED, LD and Microelectronics applications. We are always dedicated to improve the quality of currently GaAs wafer substrates and develop large size substrates. The GaAs wafer size offered is in 2”, 3”, 4” and 6”, and the thickness should be 220-700um. Moreover, the GaAs wafer price from us is competitive.

1. GaAs Wafer Specifications

1.1 (GaAs)GalliumarsenidinfraredWafer für LED-Anwendungen

| Artikel | Technische Daten | Bemerkungen |

| Conduction Typ | SC / n-Typ | SC / p-Typ mit Zn dope verfügbar |

| Growth-Methode | VGF | |

| Dotierstoff | Silizium | Zn verfügbar |

| Wafer Diamter | 2, 3 & 4 Zoll | Ingot oder als geschnittenes availalbe |

| Kristallorientierung | (100) 2 & deg;/ 6 ° / 15 ° von der (110) | Andere Fehlorientierung verfügbar |

| VON | EJ oder US | |

| Ladungsträgerkonzentration | (0,4 ~ 2,5) E18 / cm3 | |

| Der spezifische Widerstand bei RT | (1,5 ~ 9) E-3 Ohm.cm | |

| Mobilität | 1500 ~ 3000cm2 / Vsek | |

| Ätzgrübchendichte | <5000 / cm2 | |

| Laserbeschriftung | auf Anfrage | |

| Oberflächenfinish | P / E oder P / P | |

| Dicke | 220 ~ 450um | |

| Epitaxy Bereit | Ja | |

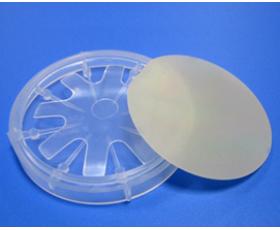

| Paket | Single-Wafer-Behälter oder Kassette | |

1.2 (GaAs)GalliumarsenidinfraredWafer für LD-Anwendungen

| Artikel | Technische Daten | Bemerkungen |

| Conduction Typ | SC / n-Typ | |

| Growth-Methode | VGF | |

| Dotierstoff | Silizium | |

| Wafer Diamter | 2, 3 & 4 Zoll | Ingot oder als geschnittene verfügbar |

| Kristallorientierung | (100) 2 & deg;/ 6 ° / 15 ° von der (110) | Andere Fehlorientierung verfügbar |

| VON | EJ oder US | |

| Ladungsträgerkonzentration | (0,4 ~ 2,5) E18 / cm3 | |

| Der spezifische Widerstand bei RT | (1,5 ~ 9) E-3 Ohm.cm | |

| Mobilität | 1500 ~ 3000 cm 2 / Vsec | |

| Ätzgrübchendichte | <500 / cm2 | |

| Laserbeschriftung | auf Anfrage | |

| Oberflächenfinish | P / E oder P / P | |

| Dicke | 220 ~ 350um | |

| Epitaxy Bereit | Ja | |

| Paket | Single-Wafer-Behälter oder Kassette | |

1.3 (GaAs)GalliumarsenidinfraredWaffeln, halbisolierendem für Mikroelektronik-Anwendungen

| Artikel | Technische Daten | Bemerkungen |

| Conduction Typ | isolierend | |

| Growth-Methode | VGF | |

| Dotierstoff | C doped | |

| Wafer Diamter | 2, 3 & 4 Zoll | Ingot available |

| Kristallorientierung | (100)+/- 0.5° | |

| VON | EJ, USA oder Kerbe | |

| Ladungsträgerkonzentration | n / A | |

| Der spezifische Widerstand bei RT | > 1E7 Ohm.cm | |

| Mobilität | > 5000 cm 2 / Vsec | |

| Ätzgrübchendichte | <8000 / cm2 | |

| Laserbeschriftung | auf Anfrage | |

| Oberflächenfinish | P / P | |

| Dicke | 350 ~ 675um | |

| Epitaxy Bereit | Ja | |

| Paket | Single-Wafer-Behälter oder Kassette | |

1.4 6″ (150mm)(GaAs)GalliumarsenidinfraredWaffeln, halbisolierendem für Mikroelektronik-Anwendungen

| Artikel | Technische Daten | Bemerkungen |

| Conduction Typ | Halbisolierendem | – |

| wachsen Methode | VGF | – |

| Dotierstoff | C doped | – |

| Typ | N | – |

| Diamater (mm) | 150 ± 0,25 | – |

| Orientierung | (100)0°±3.0° | – |

| NOTCH Orientierung | 〔010〕±2° | – |

| KERBE Deepth (mm) | (1-1.25)mm 89°-95° | – |

| Ladungsträgerkonzentration | please consult our sales team | – |

| Spezifischer Widerstand (ohm.cm) | >1.0×107 | – |

| Mobilität (cm2 / vs) | please consult our sales team | – |

| Luxation | please consult our sales team | – |

| Dicke (um) | 675 ± 25 | – |

| Randausschluss für Bogen und Warp (mm) | please consult our sales team | – |

| Bogen (um) | please consult our sales team | – |

| Warp (um) | ≤20.0 | – |

| TTV (um) | ≤10.0 | – |

| TIR (um) | ≤10.0 | – |

| LFPD (um) | please consult our sales team | – |

| Polieren | P / P Epi-Ready | – |

1.5 2″(50.8mm) LT-GaAs (Low Temperature-Gewachsen Galliumarsenid) Wafer-Spezifikationen

| Artikel | Technische Daten |

| Conduction Typ | Halbisolierendem |

| wachsen Methode | VGF |

| Dotierstoff | Sub:C doped / Epi:Undoped |

| Typ | N |

| Diamater (mm) | 150 ± 0,25 |

| Orientierung | (100)0°±3.0° |

| NOTCH Orientierung | 〔010〕±2° |

| KERBE Deepth (mm) | (1-1.25)mm 89°-95° |

| Ladungsträgerkonzentration | please consult our sales team |

| Spezifischer Widerstand (ohm.cm) | >1.0×107 or 0.8-9 x10-3 |

| Mobilität (cm2 / vs) | please consult our sales team |

| Luxation | please consult our sales team |

| Dicke (um) | 675 ± 25 |

| Randausschluss für Bogen und Warp (mm) | please consult our sales team |

| Bogen (um) | please consult our sales team |

| Warp (um) | ≤20.0 |

| TTV (um) | ≤10.0 |

| TIR (um) | ≤10.0 |

| LFPD (um) | please consult our sales team |

| Polieren | P / P Epi-Ready |

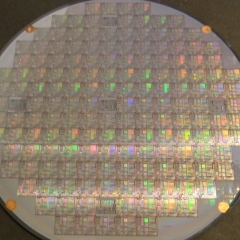

2. GaAs Wafer Market & Application

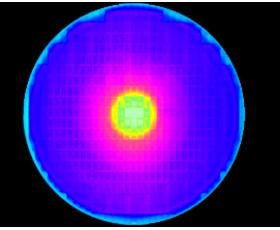

Gallium arsenide is an important semiconductor material. It belongs to group III-V compound semiconductors and the zinc blende crystal lattice structure, with a lattice constant of 5.65×10-10m, a melting point of 1237°C, and a band gap of 1.4 electron volts. Gallium arsenide can be made into semi-insulating high-resistance materials, which can be used to make integrated circuit substrates, infrared detectors, gamma photon detectors, etc. Because its electron mobility is 5 to 6 times greater than silicon, SI GaAs substrate has been importantly used in the fabrication of microwave devices and high-speed digital circuits. Semiconductor devices fabricated on gallium arsenide have the advantages of high frequency, high temperature, low temperature performance, low noise, and strong radiation resistance, which make the GaAs substrate market enlarge.

3. Test certificate of GaAs wafer can include below analysis if necessary:

1/Surface roughness of Gallium Arsenide including front side and backside(nanometers).

2/Doping concentration of Gallium Arsenide(cm-3)

3/EPD of Gallium Arsenide(cm-2)

4/Mobility of Gallium Arsendie(V.sec)

5/X-ray diffraction analysis (rocking curves) of Gallium Arsenide: Diffraction reflection curve half-width

6/Low-temperature photoluminescence (emission spectra in the range 0.7-1.0 μm) of Gallium Arsenide: The fraction of exciton photoluminescence in the emission spectrum of the near-IR range at a temperature of 4K or 5 K and an optical excitation density of 1 W / cm2

7/Transmission rate or Absorption coefficient: for instant, we can measure absorption coefficient of single crystal undoped GaAs at 1064nm: <0.6423 cm-1, and this corresponds to a transmission minimum of 33.2% for an exactly 6.5mm thick blank at 1064nm.

Remark:

The Chinese government has announced new limits on the exportation of Gallium materials (such as GaAs, GaN, Ga2O3, GaP, InGaAs, and GaSb) and Germanium materials used to make semiconductor chips. Starting from August 1, 2023, exporting these materials is only allowed if we obtains a license from the Chinese Ministry of Commerce. Hope for your understanding and cooperation!