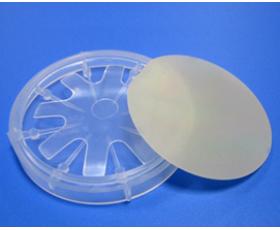

GaN-HEMT-Epitaxie-Wafer

Gallium Nitride (GaN) HEMTs (High Electron Mobility Transistors) are the next generation of RF power transistor technology. Thanks to GaN technology, PAM-XIAMEN now offer AlGaN/GaN HEMT Epi Wafer on sapphire or Silicon, and AlGaN/GaN on sapphire template.

- Beschreibung

Produktbeschreibung

GaN HEMT epitaxial wafer is a multilayer film grown epitaxially on a substrate, which usually includes a nucleation layer, a transition layer, a buffer layer, a channel layer, a barrier layer, a cap layer, and a passivation layer from bottom to top. The nucleation layer, like AlGaN or AlN, is used to prevent the substrate material from diffusing into the GaN epitaxial layer. The transition layer may contain hierarchical AlGaN, AlN/GaN superlattice or multilayer AlN to balance the stress between the GaN and the substrate. The higher the Al content in the barrier layer of AlGaN, the higher the 2DEG concentration at the heterojunction. Meanwhile, the lower the threshold voltage of the device, and the higher the current capacity. As the Al ratio increasing, the degree of heterogeneous crystal lattice mismatch will be higher, resulting in a decrease in gallium nitride HEMT electron mobility and a decrease in current capacity.

The High Electron Mobility Transistor (HEMT) is developed based on GaN with unique heterostructure and two-dimensional electron gas. The GaN HEMT advantages include high breakdown strength, low on-resistance and faster The switching speed, which is very suitable for medium and low voltage and medium and small power systems, such as travel adapters, wireless chargers, AC-DC converters, smart home appliances, etc. The epitaxial wafer with HEMT structure is more attractive currently for high-frequency converters, in which GaN HEMT breakdown voltage is 600~650 V. With the rapid development of gallium nitride HEMT epi technology, the price of GaN HEMT devices will be competitive, which can gain large GaN HEMT market for GaN HEMT manufacturers. Moreover, due to the gallium nitride HEMT reliability, it can be widely used in industrial fields, such as photovoltaic inverters, energy storage systems, and electric vehicles.

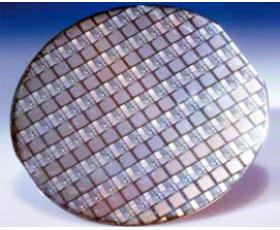

1. GaN HEMT Material: Available size:2”,4”,6”,8”:

More specific parameters of gallium nitride HEMT wafer for D-mode GaN HEMTs, E-mode GaN HEMTs, GaN HEMT power amplifier and RF, please refer to:

GaN auf Si für Energie, D-Modus

GaN auf Si für Energie, E-Modus

We are expert in HEMT structure, we also offer GaN HEMT epi wafer for many years.

For silicon substrate, we need to know if you grow GaN HEMT on silicon for POWER or RF, it is different. If needed, please contact victorchan@powerwaywafer.com for details.

For SiC, you should use semi-insulating.

Or you can buy AlGaN/GaN HEMT structure on these three structure from us.

2. Now we show you an example as follows:

2.1 2 "(50,8 mm) GaN HEMT Epitaxiewafern

We offer 2″(50.8mm) gallium nitride HEMT Wafers, the GaN HEMT structure is as follows:

Struktur (von oben nach unten):

* Undotierte GaN Kappe (2 ~ 3 nm)

AlxGa1-xN (18 ~ 40 nm)

AlN (Pufferschicht)

undotiertes GaN (2 ~ 3um)

Saphirsubstrat

* Wir können Si3n verwenden GaN auf der Oberseite zu ersetzen, ist die Haftung stark, es durch Sputter oder PECVD beschichtet ist.

2.2 AlGaN/GaN HEMT Epi Wafer on sapphire/GaN

| Schicht # | Zusammensetzung | Dicke | X | Dotierstoff | Ladungsträgerkonzentration |

| 5 | GaN | 2 nm | – | – | – |

| 4 | AlxGa1–xN | 8 nm | 0.26 | – | – |

| 3 | AlN | 1nm | Undotierte | ||

| 2 | GaN | ≥1000 nm | Undotierte | ||

| 1 | Buffer / Übergangsschicht | – | – | ||

| Substrat | Silizium | 350 um / 625μm | – | ||

2.3 2″(50.8mm),4″ (100mm)AlGaN/GaN HEMT Epi Wafer on Si

2.3.1 Specifications for Aluminium Gallium Nitride (AlGaN) / Gallium Nitride (GaN) HEMT (HEMT) auf einem Siliziumsubstrat.

| Bedarf | Spezifikation |

| AlGaN / GaN HEMT Epi-Wafer auf Si | |

| AlGaN / GaN HEMT-Struktur | siehe 1.2 |

| Substratmaterial | Silizium |

| Orientierung | <111> |

| Wachstumsverfahren | float Zone |

| Conduction Typ | P oder N |

| Größe (Zoll) | 2” , 4” |

| Dicke (um) | 625 |

| Hintern | rau |

| Der spezifische Widerstand (Ω-cm) | >6000 |

| Bogen (um) | ≤ ± 35 |

2.3.2 Epi structure: Crack-free Epilayers

| Schicht # | Zusammensetzung | Dicke | X | Dotierstoff | Ladungsträgerkonzentration |

| 5 | GaN | 2 nm | – | – | – |

| 4 | AlxGa1–xN | 8 nm | 0.26 | – | – |

| 3 | AlN | 1nm | Undotierte | ||

| 2 | GaN | ≥1000 nm | Undotierte | ||

| 1 | Buffer / Übergangsschicht | – | – | ||

| Substrat | Silizium | 350 um / 625μm | – | ||

2.3.3 Electrical Properties of the AlGaN/GaN HEMT structure

2DEG Mobility (bei 300 K): ≥1,800 cm2 / Vs

2DEG Blatt Trägerdichte (bei 300 K): ≥0.9 × 1013 cm-2

RMS-Rauhigkeit (AFM): ≤ 0,5 nm (5,0 & mgr; m × 5,0 & mgr; m-Scan-Bereich)

2.4 2″(50.8mm)AlGaN/GaN on sapphire

Zur Spezifikation von AlGaN / GaN auf Saphir-Vorlage, bitte an unsere Verkaufsabteilung: sales@powerwaywafer.com.

GaN HEMT Applications: Used in blue laser diodes, ultraviolet LEDs (down to 250 nm), and AlGaN/GaN HEMTs device.

3. Explanation of AlGaN/Al/GaN HEMTs:

Nitride HEMTs werden für Hochleistungselektronik in Hochfrequenz-Verstärkung und Leistungsschaltanwendungen intensiv entwickelt. Oft hohe Leistung in DC-Betrieb verloren, wenn der HEMT schaltet ist - zum Beispiel des auf Strom kollabiert, wenn das Gate-Signal gepulst wird. Es wird vermutet, dass solche Effekte zu Charge-Trapping in Zusammenhang stehen, dass Masken die Wirkung des Tores auf dem Stromfluss. Feldplatten auf den Source- und Gate-Elektroden sind verwendet worden, um das elektrische Feld in der Vorrichtung zu manipulieren, wie Strom-collapse Erscheinungen abzuschwächen.

4. GaN EpitaxialTechnology — Customized GaN epitaxy on SiC,Si and Sapphire substrate for HEMTs, LEDs:

GAN HEMT Epitaxiewafern (GAN EPI-WAFER)

PAM XIAMEN Offers Epitaxial growth of AlGaN/GaN based HEMT on Si wafers

5. GaN Device:

GaN HEMT

6. Test Characterization Equipment:

Berührungslose Flächenwiderstand

Laser Thin Film Dicke Mapping

High Temp / Hochfeuchte- Rückwärts-Bias

Thermoschock

DIC Nomarski-Mikroskop

Atomkraftmikroskop (AFM)

Oberflächen Fehlerhaftigkeit Scan

High Temp Rückwärts-Bias

4PP Flächenwiderstand

Contactless Halle Mobility

Temperaturzyklus

X-ray Diffraction (XRD) / Reflektanz (XRR)

Ellipsometer Dicke

Profilometer

CV Tester

7. Foundry Fabrication:

we also offer foundry GaN HEMT fabrication in the following process as follows:

MOCVD-Epitaxie

Metall-Sputter / E-Beam-

Dry / Wet Metal / Dielektrikumätzen

Thin Film PECVD / LPCVD / Sputtering

RTA / Ofentemperung

Fotolithografie (0,35 um min. CD)

Ionenimplantation

Remark:

The Chinese government has announced new limits on the exportation of Gallium materials (such as GaAs, GaN, Ga2O3, GaP, InGaAs, and GaSb) and Germanium materials used to make semiconductor chips. Starting from August 1, 2023, exporting these materials is only allowed if we obtains a license from the Chinese Ministry of Commerce. Hope for your understanding and cooperation!

More fabrication services, please visit: GaN Fabrication Services for HEMT Devices

Aluminium gallium arsenide epi wafer

650V GaN FETs Chip for Fast Charge

GaN MOSFET Structure:

GaN MOSFET Structure on SiC Substrate

More about GaN HEMT structures, please read: