PAM-XIAMEN, une entreprise de fabrication de plaquettes de silicium, propose des plaquettes de silicium : plaquette de silicium FZ, plaquette de test, plaquette de moniteur, plaquette factice, plaquette de test, plaquette CZ, plaquette épitaxiale, plaquette polie, plaquette de gravure.

Le processus de fabrication des plaquettes de silicium comprend l'extraction, le découpage en dés, le meulage, le chanfreinage, la gravure, le polissage, le nettoyage et l'inspection des cristaux, parmi lesquels l'extraction des cristaux, le polissage et l'inspection des plaquettes sont les maillons essentiels de la fabrication des plaquettes de Si. En tant que substrat semi-conducteur de base, les tranches de silicium doivent répondre à des normes élevées de pureté, de planéité de surface, de propreté et de contamination par impuretés pour conserver les fonctions conçues à l'origine de la puce. Les exigences élevées des spécifications des plaquettes de silicium semi-conductrices rendent leur processus de fabrication compliqué. Les quatre étapes principales comprennent la purification du polysilicium et le moulage des lingots de polysilicium, la croissance des tranches de Si monocristallin, ainsi que la découpe et le façonnage des tranches de Si. En tant que matière première pour la fabrication de plaquettes, la qualité des plaquettes de silicium détermine directement la stabilité du processus d'application des plaquettes. Les plaquettes de silicium de grande taille sont devenues la future tendance de développement des plaquettes de silicium. Afin d'améliorer l'efficacité de la production et de réduire les coûts, de plus en plus de tranches de silicium de grande taille sont utilisées.

-

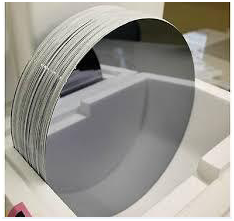

Plaquette de silicium de qualité supérieure 12″

PAM-XIAMEN propose des tranches de silicium nu de 300 mm (12 pouces) de première qualité, de type n ou de type p, et l'épaisseur de la tranche de silicium de 300 mm est de 775 ± 15. Comparé à d'autres fournisseurs de plaquettes de silicium, le prix des plaquettes de silicium de Powerway Wafer est plus compétitif et de meilleure qualité. Les tranches de silicium de 300 mm ont un rendement par tranche plus élevé que les tranches de silicium perméables de grand diamètre.

-

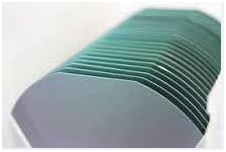

Plaquettes de silicium 12″ 300 mm TOX (plaquette d'oxydation thermique Si)

PAM-XIAMEN propose des plaquettes d'oxyde de silicium et des plaquettes de dioxyde de 300 mm. La plaquette de silicium à oxyde thermique ou la plaquette de dioxyde de silicium est une plaquette de silicium nue avec une couche d'oxyde développée par un processus d'oxydation sèche ou humide. La couche d'oxyde thermique de la plaquette de silicium est généralement cultivée dans un four tubulaire horizontal, et la plage de température de l'oxyde de la plaquette de silicium est généralement de 900 ℃ ~ 1 200 ℃. Par rapport à la couche d'oxyde CVD, la couche d'oxyde de plaquette de silicium présente une plus grande uniformité, une meilleure compacité, une rigidité diélectrique plus élevée et une meilleure qualité.

-

Plaquette de silicium de qualité test 12″

PAM-XIAMEN propose des plaquettes de silicium nues de 300 mm (12 pouces), de qualité test, de type n ou de type p. Comparé à d'autres fournisseurs de plaquettes de silicium, Powerway Wafer offre un service professionnel à des prix compétitifs.

-

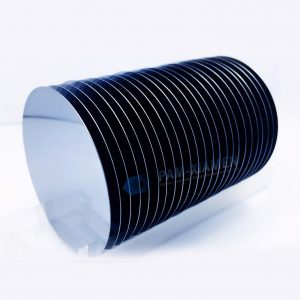

Float-Zone monocristallins Silicon

PAM-XIAMEN peut proposer une plaquette de silicium à zone flottante, obtenue par la méthode Float Zone. Les tiges de silicium monocristallin sont obtenues grâce à la croissance de la zone flottante, puis transformées les tiges de silicium monocristallin en tranches de silicium, appelées tranches de silicium à zone flottante. Étant donné que la tranche de silicium fondue dans la zone n'est pas en contact avec le creuset en quartz pendant le processus de silicium en zone flottante, le matériau de silicium est dans un état en suspension. Ainsi, il est moins pollué lors du processus de fusion du silicium en zone flottante. La teneur en carbone et en oxygène est plus faible, les impuretés sont moindres et la résistivité est plus élevée. Il convient à la fabrication d’appareils électriques et de certains appareils électroniques haute tension.

-

Test Wafer Moniteur Wafer Dummy Wafer

En tant que fabricant de plaquettes factices, PAM-XIAMEN propose des plaquettes factices en silicone / des plaquettes de test / des plaquettes de moniteur, qui sont utilisées dans un dispositif de production pour améliorer la sécurité au début du processus de production et sont utilisées pour le contrôle de livraison et l'évaluation de la forme du processus. Comme les plaquettes de silicium factices sont souvent utilisées à des fins d'expérimentation et de test, leur taille et leur épaisseur sont des facteurs importants dans la plupart des cas. Une plaquette factice de 100 mm, 150 mm, 200 mm ou 300 mm est disponible.

-

Cz monocristallins Silicon

PAM-XIAMEN, un producteur de silicium monocristallin en vrac, peut proposer des tranches de silicium monocristallin <100>, <110> et <111> avec un dopant N&P de 76,2 à 200 mm, qui sont cultivées par la méthode CZ. La méthode Czochralski est une méthode de croissance cristalline, appelée méthode CZ. Il est intégré dans un système thermique à tube droit, chauffé par une résistance en graphite, fait fondre le polysilicium contenu dans un creuset en quartz de haute pureté, puis insère le cristal germe dans la surface de la masse fondue pour le soudage. Après cela, le cristal germe en rotation est abaissé et fondu. Le corps est infiltré et touché, progressivement soulevé et fini ou tiré à travers les étapes de striction, de striction, d'épaulement, de contrôle du diamètre égal et de finition.

-

Silicon Wafer épitaxial

La plaquette épitaxiale de silicium (Epi Wafer) est une couche de monocristal de silicium épitaxial déposée sur une plaquette de silicium monocristallin (remarque : il est disponible pour faire croître une couche de couche de silicium polycristallin au-dessus d'une plaquette de silicium monocristallin hautement dopée, mais elle nécessite une couche tampon (telle que de l'oxyde ou du poly-Si) entre le substrat en Si massif et la couche supérieure de silicium épitaxial. Il peut également être utilisé pour les transistors à couches minces.

-

Wafer poli

PAM-XIAMEN peut proposer des plaquettes polies, de type n ou de type p avec une orientation à <100>, <110> ou <111>. Plaquettes polies FZ, principalement pour la production de redresseurs au silicium (SR), de redresseurs contrôlés au silicium (SCR), de transistors géants (GTR), de thyristors (GRO)

-

Eau-forte Wafer

Les tranches de silicium de gravure proposées par PAM-XIAMEN sont des tranches de gravure de type N ou P, qui ont une faible rugosité, une faible réflectivité et une réflectivité élevée. La tranche de gravure présente les caractéristiques d'une faible rugosité, d'un bon brillant et d'un coût relativement faible, et remplace directement la tranche polie ou la tranche épitaxiale qui présente un coût relativement élevé pour produire les éléments électroniques dans certains domaines, réduisant ainsi les coûts.