GaAs Epiwafer

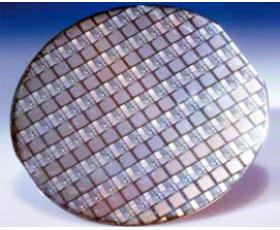

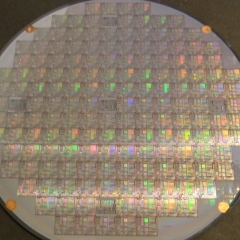

PAM-XIAMEN is manufacturing various types of epi wafer III-V silicon doped n-type semiconductor materials based on Ga, Al, In, As and P grown by MBE or MOCVD. We supply custom GaAs epiwafer structures to meet customer specifications, please contact us for more information.

- Description

Product Description

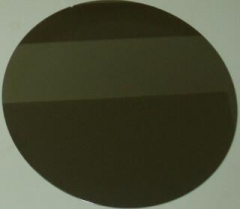

GaAs Epi wafer

As a leading GaAs epi wafer foundry, PAM-XIAMEN are manufacturing various types of epiwafer III-V silicon doped n-type semiconductor materials based on Ga, Al, In, As and P grown by MBE or MOCVD, which make a low gallium arsenide epi wafer defect. We supply custom GaAs epiwafer structures to meet customer specifications, please contact us for more information.

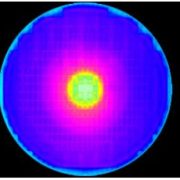

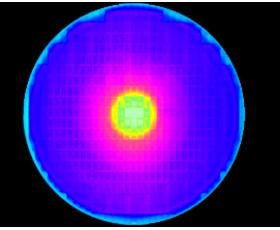

We have numbers of the United States Veeco’s GEN2000, GEN200 large-scale production of epitaxial equipment production line, full set of XRD; PL-Mapping; Surfacescan, and other world-class analysis and testing equipment. The company has more than 12,000 square meters of supporting plant, including world class super-clean semiconductor and a related research and development of the younger generation of clean laboratory facilities.

Specification for all new and featured products of MBE III-V compound semiconductor epitaxial wafer:

| Substrate Material | Material Capability | Application |

| GaAs | low temperature GaAs | THz |

| GaAs | GaAs/GaAlAs/GaAs/GaAs | Schottky Diode |

| InP | InGaAs | PIN detector |

| InP | InP/InP/InGaAsP/InP/InGaAs | Laser |

| GaAs | GaAs/AlAs/GaAs | |

| InP | InP/InAsP/InGaAs/InAsP | |

| GaAs | GaAs/InGaAsN/AlGaAs | |

| /GaAs/AlGaAs | ||

| InP | InP/InGaAs/InP | photodetectors |

| InP | InP/InGaAs/InP | |

| InP | InP/InGaAs | |

| GaAs | GaAs/InGaP/GaAs/AlInP | Solar Cell |

| /InGaP/AlInP/InGaP/AlInP | ||

| GaAs | GaAs/GaInP/GaInAs/GaAs/AlGaAs/GalnP/GalnAs | Solar Cell |

| /GalnP/GaAs/AlGaAs/AllnP/GalnP/AllnP/GalnAs | ||

| InP | InP/GaInP | |

| GaAs | GaAs/AlInP | |

| GaAs | GaAs/AlGaAs/GalnP/AlGaAs/GaAs | 703nm Laser |

| GaAs | GaAs/AlGaAs/GaAs | |

| GaAs | GaAs/AlGaAs/GaAs/AlGaAs/GaAs | HEMT |

| GaAs | GaAs/AlAs/GaAs/AlAs/GaAs | mHEMT |

| GaAs | GaAs/DBR/AlGaInP/MQW/AlGaInP/GaP | LED wafer,solid state lighting |

| GaAs | GaAs/GalnP/AlGaInP/GaInP | 635nm,660nm,808nm,780nm, 785nm, |

| /GaAsP/GaAs/GaAs substrate | 950nm, 1300nm,1550nm Laser | |

| GaSb | AlSb/GaInSb/InAs | IR detector,PIN,sensing, IR cemera |

| silicon | InP or GaAs on Silicon | High speed IC/microprocessors |

| InSb | Beryllium doped InSb | |

| / undoped InSb/Te doped InSb/ |

Gallium arsenide is currently one of the most important compound semiconductor materials with the highest mature epi wafer technology. GaAs material has the characteristics of large forbidden band width, high electron mobility, direct band gap, high luminous efficiency. Due to all all these epi wafer advantages, GaAs epitaxy is currently the most important material used in the field of optoelectronics. Meanwhile, it is also an important microelectronic material. According to the difference in electrical conductivity, GaAs epi wafer materials can be divided into semi-insulating (SI) GaAs and semiconductor (SC) GaAs.

In the field of epitaxial wafers, the epi wafer market share of RF and laser applications is very large.

For more detail specification, please review the following:

LT-GaAs epi layer on GaAs substrate

LT GaAs Thin Film for Photodetectors and Photomixers

GaAs Schottky Diode Epitaxial Wafers

InGaAsP/InGaAs on InP substrates

InGaAs APD Wafers with High Performance

InGaAsN epitaxially on GaAs or InP wafers

Structure for InGaAs photodetectors

AlGaP/GaAs Epi Wafer for Solar Cell

Solar Cell Structure Epitaxially Grown on InP Wafer

Growth of GaAsSb / InGaAs Type-II Superlattice

Layer structure of 703nm Laser

AlGaAs / GaAs PIN Epitaxial Wafer

1550nm GaInAsP / InP PIN Photodiode Structure

Now we list some specifications:

| GaAs HEMT epiwafer, size:2~6inch | ||

| Item | Specifications | Remark |

| Parameter | Al composition/In composition/Sheet resistance | Please contact our tech department |

| Hall mobility/2DEG Concentration | ||

| Measurement tech | X-ray diffraction/Eddy current | Please contact our tech department |

| Un-contact hall | ||

| Typical valve | Struture dependent | Please contact our tech department |

| 5000~6500cm2/V ·S/0.5~1.0x 1012cm-2 | ||

| Standard tolerance | ±0.01/±3%/none | Please contact our tech department |

| GaAs(gallium arsenide) pHEMT epiwafer, size:2~6inch | ||

| Item | Specifications | Remark |

| Parameter | Al composition/In composition/Sheet resistance | Please contact our tech department |

| Hall mobility/2DEG Concentration | ||

| Measurement tech | X-ray diffraction/Eddy current | Please contact our tech department |

| Un-contact hall | ||

| Typical valve | Struture dependent | Please contact our tech department |

| 5000~6800cm2/V ·S/2.0~3.4x 1012cm-2 | ||

| Standard tolerance | ±0.01/±3%/none | Please contact our tech department |

| Remark:GaAs pHEMT: Compared with GaAs HEMT, GaAs PHEMT also incorporates InxGa1-xAs,where InxAs is constrained to x < 0.3 for GaAs-based devices. Structures grown with the same lattice constant as HEMT, but different band gaps are simply referred to as lattice-matched HEMTs. | ||

| GaAs mHEMT epiwafer, size:2~6inch | ||

| Item | Specifications | Remark |

| Parameter | In composition/Sheet resistance | Please contact our tech department |

| Hall mobility/2DEG Concentration | ||

| Measurement tech | X-ray diffraction/Eddy current | Please contact our tech department |

| Un-contact hall | ||

| Typical valve | Struture dependent | Please contact our tech department |

| 8000~10000cm2/V ·S/2.0~3.6x 1012cm-2 | ||

| Standard tolerance | ±3%/none | Please contact our tech department |

| InP HEMT epiwafer, size:2~4inch | ||

| Item | Specifications | Remark |

| Parameter | In composition/Sheet resistance/Hall mobility | Please contact our tech department |

Remark: GaAs(Gallium arsenide) is a compound semiconductor material,a mixture of two elements, gallium (Ga) and arsenic (As). The uses of Gallium arsenide are varied and include being used in LED/LD, field-effect transistors (FETs), and integrated circuits (ICs)

Device applications

RF Switch, Power and low-noise amplifiers, Hall sensor, Optical modulator

Wireless: cell phone or base stations

Automotive radar, MMIC, RFIC, Optical Fiber Communications

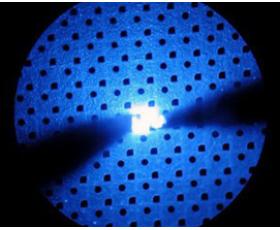

GaAs Epi Wafer for LED/IR serie:

1.General description:

1.1 Growth Method: MOCVD

1.2 GaAs epi wafer for Wireless Networking

1.3 GaAs epi wafer for LED /IR and LD/PD

2.Epi wafer specs:

2.1 Wafer size: 2”diameter

2.2 GaAs Epi Wafer Structure(from top to bottom):

P + GaAs

p-GaP

p-AlGaInP

MQW-AlGaInP

n-AlGaInP

DBR n-ALGaAs / AlAs

Buffer

GaAs substrate

3.Chip sepcification (Base on 9mil*9mil chips)

3.1 Parameter

Chip Size 9mil*9mil

Thickness 190±10um

Electrode diameter 90um±5um

3.2 Optical-elctric characters(Ir=20mA,22℃)

Wavelength 620~625nm

Forward voltage 1.9~2.2v

Reverse voltage ≥10v

Reverse current 0-1uA

3.3 Light intensity characters(Ir=20mA,22℃)

IV (MCD) 80-140

3.4 Epiwafer avelength

|

Item |

Unit |

Red |

Yellow |

Yellow/Green |

Description |

|

Wave Length (λD) |

nm |

585,615,620 ~ 630 |

587 ~ 592 |

568 ~ 573 |

IF =20mA |

Growth Methods:MOCVD,MBE

epitaxy = growth of film with a crystallographic relationship between film and substrate homoepitaxy (autoepitaxy, isoepitaxy) = film and substrate are same material heteroepitaxy = film and substrate are different materials. For more information of growth methods, please click the following: https://www.powerwaywafer.com/technology.html

Remark:

The Chinese government has announced new limits on the exportation of Gallium materials (such as GaAs, GaN, Ga2O3, GaP, InGaAs, and GaSb) and Germanium materials used to make semiconductor chips. Starting from August 1, 2023, exporting these materials is only allowed if we obtains a license from the Chinese Ministry of Commerce. Hope for your understanding and cooperation!

InGaAs Epitaxy Sensor / Detector:

Shortwave Infrared InGaAs Sensor

InGaAs/InAlAs Epistucture for Single Photon Detector

Epiwafer for Photonic Integrated Chip: