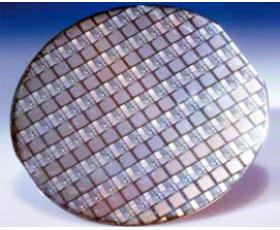

InAsのウェハ

PAM-XIAMEN は、化合物半導体 InAs ウェハ、つまり N 型、p 型、または異なる方向 (111) または (100) の半絶縁性を備えたエピレディまたはメカニカルグレードとして LEC (Liquid Encapsulated Czochralski) によって成長させたインジウムヒ素ウェハを提供しています。 さらに、InAs 単結晶は電子移動度が高く、ホール素子の作製に最適な材料です。

- 説明

製品の説明

PAM-XIAMEN は化合物半導体 InAs ウェーハを提供 –インジウムヒ素LEC(Liquid Encapsulated Czochralski)によってエピレディまたはメカニカルグレードとしてn型、p型、または半絶縁性の異なる方位(111)(100)または(110)で成長したウェーハ。 さらに、InAs 単結晶は電子移動度が高く、ホール素子の作製に最適な材料です。

インジウムヒ素、InAs は、インジウムとヒ素から構成される半導体です。 融点 942 °C、格子定数 0.6058 nm の灰色の立方体結晶の外観を持ち、ヒ化インジダムの結晶構造は閃亜鉛鉱構造です。 インジウムヒ素ウェハは、1 ~ 3.8 µm の波長範囲の赤外線検出器の構築に使用されます。 検出器は通常、光起電力フォトダイオードです。 極低温冷却された検出器はノイズが低くなりますが、InAs 検出器は室温でも高出力アプリケーションに使用できます。 インジウムヒ素の優れた特性により、インジウムヒ素薄膜はダイオードレーザーの製造にも使用されます。

インジウムヒ素のバンドギャップはガリウムヒ素と同様の直接遷移であり、禁制帯幅は(300K)0.45eVです。 インジウムヒ素は、リン化インジウムと一緒に使用されることがあります。 ガリウムヒ素と合金化すると、In/Ga比に依存するバンドギャップを持つ材料であるインジウムガリウムヒ素が形成されます。これは主に窒化インジウムと窒化ガリウムを合金化して窒化インジウムガリウムを生成するのと同様の方法です。

ここでは詳細な仕様は次のとおりです。

2 "(50.8ミリメートル)のInAsウェーハ仕様

3 "(76.2ミリメートル)のInAsウェーハの仕様

4」(100ミリメートル)のInAsウェーハ仕様

2インチInAsウェーハ仕様

| アイテム | 仕様 | |||

| ドーパント | 低ドープ | スタナム | 硫黄 | 亜鉛 |

| 伝導型 | N型 | N型 | N型 | P型 |

| ウェーハ直径 | 2 " | |||

| ウェーハの向き | (111)±0.5°、(110)±0.5° | |||

| ウェーハの厚さ | 500±25um | |||

| 一次平坦長さ | 16±2mm | |||

| 二次平坦長さ | 8±1mm | |||

| キャリア濃度 | 5×1016cm-3 | (5-20)x1017cm-3 | (1-10)x1017cm-3 | (1-10)x1017cm-3 |

| モビリティ | ≧2×104cm2/Vs | 7000-20000cm2/Vs | 6000-20000cm2/Vs | 100-400cm2/Vs |

| EPD | <5×104cm-2 | <5×104cm-2 | <3×104cm-2 | <3×104cm-2 |

| TTV | <10um | |||

| 弓 | <10um | |||

| ワープ | <12um | |||

| レーザーマーキング | 要求に応じて | |||

| 表面仕上げ | P / E、P / P | |||

| エピ準備 | はい | |||

| パッケージ | 枚葉式ウェーハコンテナまたはカセット | |||

3インチInAsウェーハ仕様

| アイテム | 仕様 | |||

| ドーパント | 低ドープ | スタナム | 硫黄 | 亜鉛 |

| 伝導型 | N型 | N型 | N型 | P型 |

| ウェーハ直径 | 3 " | |||

| ウェーハの向き | (111)±0.5°、(110)±0.5° | |||

| ウェーハの厚さ | 600±25um | |||

| 一次平坦長さ | 22±2mm | |||

| 二次平坦長さ | 11±1mm | |||

| キャリア濃度 | 5×1016cm-3 | (5-20)x1017cm-3 | (1-10)x1017cm-3 | (1-10)x1017cm-3 |

| モビリティ | ≧2×104cm2/Vs | 7000-20000cm2/Vs | 6000-20000cm2/Vs | 100-400cm2/Vs |

| EPD | <5×104cm-2 | <5×104cm-2 | <3×104cm-2 | <3×104cm-2 |

| TTV | <12um | |||

| 弓 | <12um | |||

| ワープ | <15um | |||

| レーザーマーキング | 要求に応じて | |||

| 表面仕上げ | P / E、P / P | |||

| エピ準備 | はい | |||

| パッケージ | 枚葉式ウェーハコンテナまたはカセット | |||

4インチInAsウェーハ仕様

| アイテム | 仕様 | |||

| ドーパント | 低ドープ | スタナム | 硫黄 | 亜鉛 |

| 伝導型 | N型 | N型 | N型 | P型 |

| ウェーハ直径 | 4 " | |||

| ウェーハの向き | (111)±0.5°、(110)±0.5° | |||

| ウェーハの厚さ | 900±25um | |||

| 一次平坦長さ | 16±2mm | |||

| 二次平坦長さ | 8±1mm | |||

| キャリア濃度 | 5×1016cm-3 | (5-20)x1017cm-3 | (1-10)x1017cm-3 | (1-10)x1017cm-3 |

| モビリティ | ≧2×104cm2/Vs | 7000-20000cm2/Vs | 6000-20000cm2/Vs | 100-400cm2/Vs |

| EPD | <5×104cm-2 | <5×104cm-2 | <3×104cm-2 | <3×104cm-2 |

| TTV | <15um | |||

| 弓 | <15um | |||

| ワープ | <20um | |||

| レーザーマーキング | 要求に応じて | |||

| 表面仕上げ | P / E、P / P | |||

| エピ準備 | はい | |||

| パッケージ | 枚葉式ウェーハコンテナまたはカセット | |||

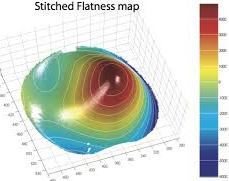

InAsウェーハのステッチ平坦度マップ

ウェハ仕様(例):

1)2” (50.8ミリメートル)のInAs

タイプ/ドーパント:N/S

方向:[111B]±0.5°

厚さ:500±25um

エピ対応

SSP

2)2” (50.8ミリメートル)のInAs

タイプ/ドーパント:N/低ドープ

方向: (111)B

厚さ:500um±25um

SSP

3)2” (50.8ミリメートル)のInAs

タイプ/ドーパント:N / 低ドープ

方位 : <111>A ±0.5°

厚さ:500um±25um

エピ対応

Ra<=0.5nm

キャリア濃度(cm-3):1E16~3E16

移動度(cm -2 ):>20000

EPD(cm -2 ):<15000

SSP

4)2” (50.8ミリメートル)のInAs

タイプ/ドーパント:N/低ドープ

方向: <100> と [001]OF

厚さ:2mm

ASカット

5)2” (50.8ミリメートル)のInAs

タイプ/ドーパント:N/P

方向:(100)、

キャリア濃度(cm-3):(5-10)E17、

厚さ:500μm

SSP

6)インジウムヒ素ウェーハ、

2”Ø×500±25μm、

p型InAs:Zn

(110)±0.5°、

Nc=(1-3)E18/cc 、

両面研磨、

枚葉カセットに窒素雰囲気下で密封されています。

すべてのウェーハは、高品質のエピタキシー準備仕上げで提供されています。 表面は、Surfscan(登録商標)ヘイズ及び粒子監視、分光エリプソメトリと斜入射干渉計を含む、社内、高度な光学計測技術によって特徴付けられます

ウェハのInAs、n型(1 0 0)における表面電子蓄積層の光学的性質にアニーリング温度の影響は、ラマン分光法によって研究されてきました。 それにより、非選別LOフォノンによる散乱のラマンピークはInAsの表面に電子蓄積層をアニールによって除去されていることを示す温度上昇と共に消失することを示します。 関与するメカニズムは、X線光電子分光法、X線回折および高分解能透過型電子顕微鏡により分析しました。 結果は、非晶質のIn 2 O 3及びAs 2 O 3相が焼鈍時のInAs表面に形成されていることを示しており、一方、酸化層とウエハとの間の界面における層のような薄い結晶は、表面電子の蓄積の厚さの減少につながるが生成されます吸着原子がアクセプタ型の表面状態を導入したよう以来の層。

InAsの発光波長は3.34μmであり、格子整合したIn-GaAsSb、InAsPSb、InAsSbマルチエピタキシャル材料をインジウム砒素基板上に成長させることができ、2~4μm帯の光ファイバー通信用のレーザーや検出器を製造できます。

当社では、InAs ウェーハ エピ サービスも提供しています。例として以下を取り上げます。

2インチサイズInAsエピウェハ(PAM190730-INAS):

エピ層:厚さ0.5μm、InAsエピ層(アンドープ、n型)、

基板:2 インチ半絶縁性 GaAs

InAs エピウェーハの詳細については、以下を参照してください。