우리는 제공한다 LT-GaAs로 wafer for THz, detector, ultra-fast-optical experiments and other applications.

1. 2 ″ LT-GaAs 웨이퍼 사양 :

| 명세서 | |

| Diamater (mm) | 1mm ± Ф의이 50.8mm |

| 두께 | 1-2um 또는 2-3um |

| 마르코 결함 밀도 | ≤ 5cm -2- |

| 저항 (300K) | > 108 옴 cm |

| 담체 | <1ps |

| 전위 밀도 | <1 × 106cm-2 |

| 쓸모있는 표면적 | ≥80 % |

| 세련 | 단일면 광택을 |

| 기판 | GaAs 기판 |

비고 : 기타 조건 :

1) GaAs 기판은 (100) 방향으로 도핑 / 반 절연되어야합니다.

2) 성장 온도 : ~ 200-250 C

2. LT-GaAs 소개 :

저온 성장 갈륨 비소 광 전도성 THz 방출기 또는 검출기의 제조에 가장 널리 사용되는 재료입니다. 고유 한 특성은 우수한 캐리어 이동성, 높은 암 저항률 및 서브 피코 초 캐리어 수명입니다.

하부 300 ° C 이상의 온도에서 분자 빔 에피 택시 (MBE)에 의해 성장 된 갈륨 비소 (LT 갈륨 비소) presents a 1%–2% arsenic excess which depends on the growth temperature Tgand on the arsenic pressure during the deposition. As a result a high density of arsenic antisite defects AsGa is produced and forms a donor miniband close to the center of the band gap. The concentration of AsGa increases with decreasing Tg and can reach 1019–1020 cm-3, which leads to a decrease of the resistivity due to hopping conduction. The concentration of ionized donors AsGa+, which are responsible for the fast electron trapping, depends strongly on the concentration of acceptors (gallium vacancies). The LT-MBE grow GaAs samples are then usually thermally annealed: The excess arsenic precipitates into metallic clusters surrounded by depleted regions of As/GaAs barriers which allow one to recover the high resistivity. The role of the precipitates in the fast carrier recombination process is, however, not yet completely clear. Recently, attempts have been made also to dope LT GaAs during the MBE growth with compensating acceptors, namely with Be, in order to increase the number of AsGa+ : the trapping time reduction was observed for heavily doped samples.

3. LT-GaAs 테스트 보고서 :

LT-갈륨 비소 보고서를 보려면 다음을 클릭하세요 :

https://www.powerwaywafer.com/low- temperature-gaas-2.html

4. LT-GaA에서 THz 생성 프로세스

https://www.powerwaywafer.com/THz-Generation-Process-in-LT-GaAs.html

5. 테라 헤르츠 광전도 안테나의 성능 :

이 문서를 보려면 다음을 클릭하세요 :

https://www.powerwaywafer.com/performance-of-terahertz-photoconductive-antennas.html

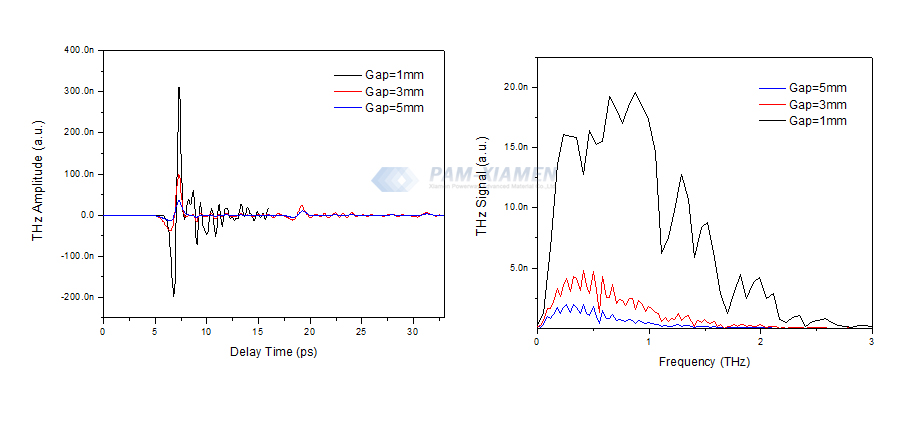

6. THz의 시간 영역 스펙트럼

아래는 LT-GaAs 웨이퍼로 만든 THz의 시간 영역 스펙트럼입니다.

THz의 시간 영역 스펙트럼

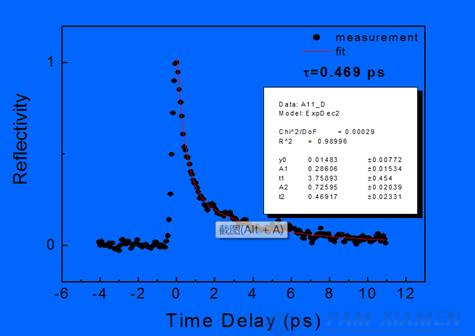

7. LT-GaAs 웨이퍼의 시간 분해 스펙트럼

LT-GaAs 웨이퍼의 시간 분해 스펙트럼

8. FAQ of LT-GaAs Wafer

Q1: Can LT-GaAs substrate be passivated? Does washing the surface with ultrasonics have any effect on that layer of low temperature GaAs?

A: The LT-GaAs substrate can do passivation treatment. It is no problem that wash the surface of LT-GaAs with low-power ultrasonic waves.

Q2: I do photolithography to deposit insulating layer, such as SiO2 100 nm, and metal electrode of Cr 10 nm/ Au 100 nm on LT-GaAs wafer. After the fabrication, I inject a pulsed laser to generate a pulsed charge current. This light-to-charge conversion is done at ambient air at room temperature. The device looks good initially, but after several usage the Au electrode part looks bumpy. (I checked it with a microscope.) I guess the bumpy shape is because water molecules that were unintentionally present in between GaAs and SiO2 or between SiO2 and Cr/Au evaporate by the laser-induced heating. Do have any idea to avoid this issue?

A: We haven’t met this situation before, you can bake the LT GaAs substrate before plating metal, but the temperature should be not too high, below 300 degrees. In addition, you need to rinse the film with dilute acid before making the metal process.

Q3: For low-temperature grown GaAs, we need to work under the scanning tunneling microscope, but the resistivity is too large to tunnel. So, is it possible to reduce the resistivity preferably to below 1M ohm/mm of the epitaxial layer (along the surface direction) by doping? There are no requirements for the elements to be doped and the method of doping.

A: The electrical resistivity of LT-GaAs epi thin film would be able to drop below 1M ohm/mm. Specific technology inquiries please contact victorchan@powerwaywafer.com.

9. Related Products:

LT 갈륨 비소 웨이퍼

LT-GaAs로의 광 스위치

LT-GaAs로 캐리어 수명

LT GaAs로 테라 헤르츠

batop의 LT-GaAs로

출처 : PAM-XIAMEN

For more information, please contact us email at victorchan@powerwaywafer.com 과 powerwaymaterial@gmail.com.