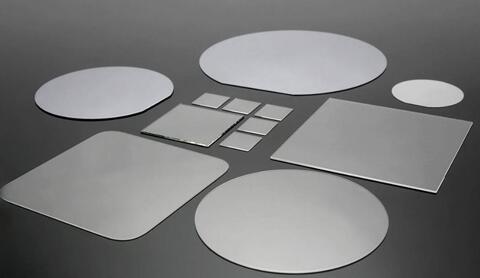

LaAlO3 (Lanthanum Aluminate) substrate is available for. LaAlO3 substrate is commonly used for epitaxial growth of thin films such as high Tc superconductors, magnetic and ferroelectric materials. The dielectric properties of LaAlO3 crystal make it suitable for low loss microwave and dielectric resonance electronics applications. PAM-XIAMEN supplies can supply a wide range of LaAlO3 single crystals and epi-ready crystal substrates to meet customer’s specific requirements.

1. LaAlO3 Substrate Specifications

Item 1:

| Main Parameters of Lanthanum Aluminate Substrates | ||

| Crystal system | Hexagonal (room temperature) | Cube (> 435 ℃) |

| Lattice constant | Hexagonal a = 5.357A c = 13.22 A | Cubic a = 3.821 A |

| Melting point (℃) | 2080 | |

| Density | 6.52 (g/cm 3) | |

| Hardness | 6-6.5 (mohs) | |

| Thermal expansion coefficient | 9.4×10^-6 / ℃ | |

| Permittivity | ε = 21 | |

| Loss tangent (10 GHz) | ~ 3 × 10^-4 @ 300K, ~ 0.6 × 10^-4 @ 77K | |

| Color and Appearance | Based on annealing conditions, from brown-yellow to brown color. Polished substrate surface shows natural twinned domain | |

| Chemical stability | Insoluble in mineral acids at 25 ℃ and soluble in H3PO3 at> 150 ℃ | |

| Growth method | Czochralski method | |

| Size | 10×3, 10×5, 10×10, 15×15, 20×15, 20×20, other sizes available upon request | |

| Ф15, Ф20, Ф1 “, Ф2”, Ф2.6 “ | ||

| Thickness | 0.5mm, 1.0mm | |

| Polishing | Single or double side polished | |

| Crystal orientation | <100> <110> <111> | |

| Crystal orientation accuracy | ± 0.5 ° | |

| Edge orientation accuracy | 2 ° (special request up to within 1 °) | |

| Miter chip | According to specific needs, the processing of the edge orientation in a specific crystal plane inclined at an angle (tilt angle of 1 ° -45 °) of the wafer | |

| Ra: | ≤ 5Å (5μm × 5μm) epi-ready | |

Item 2:

Lanthanum Aluminate (LaAl2O3) Substrate PAM190625-LA

Orientation: (100)+/-0.5deg.

Diameter: 50mm+/-0.3mm

Thickness: 0.5mm (500microns)

1 side Polished, EPI Polished

Roughness: <5A

2. Properties of LaAlO3 Wafer Substrate

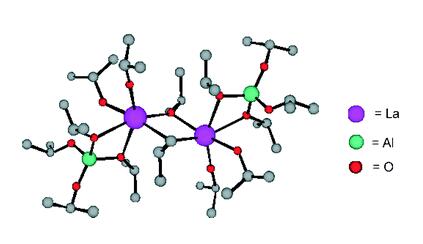

At room temperature, lanthanum aluminate space group belongs to the trigonal crystal system (symmetry group R3c), which is formed by rotating the AlO6 octahedron in the cubic phase around a cubic axis at an angle ф. When the temperature rises, lanthanum aluminate enters the cubic crystal system, and the symmetry group is Pm3m. Due to the rotation of the AlO6 octahedron, the unit cell volume doubles. Therefore, the zero-point phonons in the R3c structure come from the Γ(0, 0, 0) and R (1/2, 1/2, 1/2) point mode, this phase change can be represented by the soft mode of the Brillouin zone. The LaAlO3 crystal structure is shown as the following Fig.:

Lanthanum aluminate belongs to the ABO3 compound with pseudo-cubic perovskite structure. The color of LaAlO3 crystal is directly related to the purity of the raw materials. If the raw materials with a purity of ≤99.9% are used or the raw materials are contaminated during the growth process, the lanthanum aluminate crystal substrate will produce a darker crystal color, even brown. However, when high-purity raw materials ≥99.999% are used, the grown crystals are light yellow, and when annealed in a vacuum atmosphere, the color is light. And the lanthanum aluminate crystal is single crystal, which is almost white.

LaAlO3 is a dielectric material with excellent performance. It has a dielectric constant about 25, and the LaAlO3 band gap is 5eV. It matches well with the Si lattice. The lattice mismatch rate between LaAIO3 and superconducting materials is very small, and it has quite good chemical stability. Therefore, lanthanum aluminate is widely used as a substrate material.

3. Applications of LaAlO3 Substrate

LaAlO3 single crystal has been studied for a long time as a substrate material for high-temperature superconducting thin films and ferroelectric thin films, and is currently the most important material of choice for industrialized, large-size high-temperature superconducting thin film substrates. In addition, LaAlO3 wafer has low dielectric loss in the microwave band, so LaAlO3 substrate is also epitaxially grown high-temperature superconducting thin films and giant magnets and suitable substrate material for the barrier film.

Lanthanum aluminate substrate with its superior performance has become a high YBCO material, especially suitable for the growth of superconducting films for microwaves. It has realized the epitaxial growth of YBCO films on the bottom of LaAIO3 substrate.

LaAlO3 is often used as a buffer layer material gate between the ferroelectric film and the substrate. Research in recent years has shown that LaAlO3 film material as a high-k material has become a very promising alternative to SiO2 for the next generation of highly integrated metal-oxide-semiconductor field effect transistor (MOSFET) gate dielectric materials.

For more information, please send us email at victorchan@powerwaywafer.com and powerwaymaterial@gmail.com