SiC Epitaxy

- Penerangan

Penerangan Produk

SiC Epitaxy

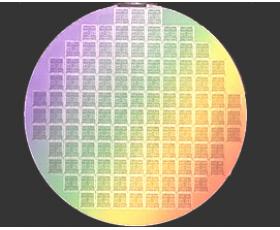

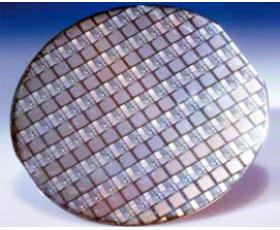

PAM-XIAMEN menyediakan filem nipis tersuai (silikon karbida) epitaksi SiC pada substrat 6H atau 4H untuk pembangunan peranti silikon karbida. Wafer epi SiC digunakan terutamanya untuk fabrikasi peranti kuasa 600V~3300V, termasuk SBD, JBS, PIN, MOSFET, JFET, BJT, GTO, IGBT, dll. Dengan wafer silikon karbida sebagai substrat, pemendapan wap kimia (CVD ) kaedah biasanya digunakan untuk mendepositkan lapisan kristal tunggal pada wafer untuk membentuk wafer epitaxial. Antaranya, epitaksi SiC disediakan dengan menumbuhkan lapisan epitaxial silikon karbida pada substrat silikon karbida konduktif, yang boleh dibuat lagi menjadi peranti kuasa.

1. Spesifikasi epitaxy SiC:

| barangan | Spesifikasi | Nilai tipikal |

| Poly-jenis | 4H | — |

| Off-orientasi ke arah | 4 deg-off | — |

| <11 2_ 0> | ||

| kekonduksian | n-jenis | — |

| Dopant | Nitrogen | — |

| Konsentrasi Pembawa | 5E15-2E18 cm-3 | — |

| toleransi | ± 25% | ± 15% |

| keseragaman | 2 "(50.8mm) <10% | 7% |

| 3 "(76.2 mm) <20% | 10% | |

| 4 "(100mm) <20% | 15% | |

| Julat ketebalan | 5-15 mikron | — |

| toleransi | ± 10% | ± 5% |

| keseragaman | 2 "<5% | 2% |

| 3 "<7% | 3% | |

| 4 "<10% | 5% | |

| Kecacatan Point besar | 2 "<30 | 2 "<15 |

| 3 "<60 | 3 "<30 | |

| 4 "<90 | 4 "<45 | |

| Kecacatan Epi | ≤20 cm-2 | ≤10 cm-2 |

| bunching langkah | ≤2.0nm (Rq) | ≤1.0nm (Rq) |

| (Kekasaran) |

Pengecualian tepi 2 mm untuk 50.8 dan 76.2 mm, pengecualian tepi 3 mm untuk 100.0 mm Catatan:

• Purata semua titik pengukuran untuk ketebalan dan kepekatan pembawa (lihat halaman 5)

• Lapisan epi jenis N <20 mikron didahului oleh lapisan penyangga n-type, 1E18, 0.5 mikron

• Tidak semua ketumpatan doping tersedia dalam semua ketebalan

• Keseragaman: sisihan piawai (σ) / purata

• Keperluan khas pada parameter epi adalah berdasarkan permintaan

2. Pengenalan SiC Epitaxy

Mengapa Kami Memerlukan Wafer Epitaxial Silicon Carbide?Kerana berbeza daripada proses pembuatan peranti kuasa silikon tradisional, peranti kuasa silikon karbida tidak boleh dibuat secara langsung pada bahan kristal tunggal silikon karbida. Bahan epitaxial berkualiti tinggi mesti ditanam pada substrat kristal tunggal konduktif, dan pelbagai peranti yang dihasilkan pada wafer epitaxial SiC.

Teknologi epitaksi utama untuk pertumbuhan epitaksi SiC ialah pemendapan wap kimia (CVD), yang merealisasikan ketebalan tertentu dan bahan epitaksi silikon karbida terdop melalui pertumbuhan aliran langkah reaktor epitaksi SiC. Dengan peningkatan keperluan pembuatan peranti kuasa silikon karbida dan menahan tahap voltan, wafer epi SiC terus berkembang ke arah kecacatan rendah dan epitaksi tebal.

Dalam beberapa tahun kebelakangan ini, kualiti bahan epitaxial silikon karbida nipis (<20 μm) telah dipertingkatkan secara berterusan. Kecacatan mikrotubul dalam bahan epitaxial telah dihapuskan. Walau bagaimanapun, kecacatan epitaksi SiC, seperti kejatuhan, segi tiga, lobak merah, kehelan skru, kehelan satah basal, kecacatan tahap dalam, dll., menjadi faktor utama yang mempengaruhi prestasi peranti. Dengan kemajuan proses epitaksi SiC, ketebalan lapisan epitaxial telah berkembang daripada beberapa μm dan puluhan μm pada masa lalu kepada puluhan μm dan ratusan μm semasa. Terima kasih kepada kelebihan SiC berbanding Si, pasaran epitaksi SiC berkembang pesat.

Oleh kerana peranti silikon karbida mesti dibuat pada bahan epitaxial, pada asasnya semua bahan kristal tunggal silikon karbida akan digunakan sebagai filem epitaxial SiC untuk mengembangkan bahan epitaxial. Teknologi bahan epitaxial silikon karbida telah berkembang pesat di peringkat antarabangsa, dengan ketebalan epitaxial tertinggi mencapai lebih daripada 250 μm. Antaranya, teknologi epitaksi 20 μm ke bawah mempunyai kematangan yang tinggi. Ketumpatan kecacatan permukaan telah dikurangkan kepada kurang daripada 1/cm2, dan ketumpatan kehelan telah dikurangkan daripada 105/cm2 kepada 103/cm2. Kadar penukaran kehelan satah asas adalah hampir 100%, yang pada asasnya telah memenuhi keperluan bahan epitaxial untuk pengeluaran peranti silikon karbida secara besar-besaran.

Dalam tahun-tahun kebelakangan ini, teknologi bahan epitaxial antarabangsa 30 μm~50 μm juga telah matang dengan cepat, tetapi disebabkan oleh pengehadan permintaan pasaran epi SiC, kemajuan perindustrian menjadi perlahan. Pada masa ini, syarikat perindustrian boleh menawarkan bahan epitaxial silikon karbida dalam kelompok, termasuk epitaksi Cree SiC, epitaksi PAM-XIAMEN SiC, epitaksi Dow Corning SiC dll.

3. Kaedah Ujian

No.1. kepekatan pembawa: doping Net ini telah dipilih sebagai nilai purata seluruh afer menggunakan Hg siasatan CV.

No.2. Ketebalan: Ketebalan ini telah dipilih sebagai nilai purata seluruh wafer menggunakan FTIR.

kecacatan titik No.3.Large: pemeriksaan mikroskopik dilakukan pada 100X, atas optik mikroskop Olympus, atau setanding.

No.4. Pemeriksaan Kecacatan Epi atau peta kecacatan yang dilakukan di bawah KLA-Tencor Candela CS20 Optical Surface Analyzer atau SICA.

No.5. Langkah bunching: Langkah bunching dan Kekasaran sedang scaned oleh AFM (daya atom mikroskop) di kawasan x10μm 10μm

3-1:Perihalan Kecacatan Mata Besar

Kecacatan yang mempamerkan bentuk yang jelas dengan mata tanpa bantuan dan> 50microns seluruh. Ciri-ciri ini termasuk pancang, zarah pengikut, cip andcraters. kecacatan titik besar kurang daripada 3 mm selain dikira sebagai satu kecacatan.

3-2: Penerangan Kecacatan Epitaksi

Kecacatan epitaksi SiC termasuk kemasukan 3C, ekor komet, lobak merah, zarah, titisan silikon dan kejatuhan.

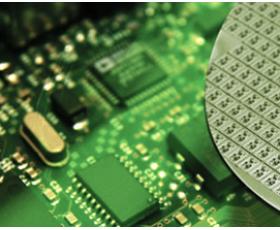

4. Penggunaan wafer epitaxial SiC

pembetulan faktor kuasa (PFC)

PV penyongsang dan (bekalan kuasa tanpa gangguan) penyongsang UPS

pemacu motor

pembetulan output

Hibrid atau elektrik kenderaan

SiC Schottky Diod dengan 600V, 650V, 1200V, 1700V, 3300V boleh didapati.

Sila lihat aplikasi terperinci di bawah mengikut bidang:

| Padang | Frekuensi Radio (RF) | Peranti Kuasa | LED |

| Bahan | SiLDMOS | Si | GaN / Al2O3 |

| GaAs | GaN / Si | GaN / Si | |

| GaN / SiC | SiC / SiC | GaN / SiC | |

| GaN / Si | Ga203 | / | |

| Peranti | GaN HEMT berasaskan SiC | MOSFET berasaskan SiC BJT berasaskan SiC IGBT berasaskan SiC SBD berasaskan SiC |

/ |

| Permohonan | Radar, 5G | Kenderaan elektrik | Pencahayaan Keadaan Pepejal |

5. Wafer mekanikal dengan lapisan Epi: tersedia, seperti untuk pemantauan proses, yang memerlukan wafer dengan busur rendah dan melengkung.

150mm 4H n-jenis wafer SiC EPI

Epilayer SiC Intrinsik pada substrat Silicon karbida

Mengapa Kami Memerlukan Wafer Epitaxial Silicon Carbide?

Struktur MOSFET SiC Homoepitaxial pada substrat SiC