PAM-XIAMEN, syarikat pembuatan wafer silikon, menawarkan wafer silikon: wafer silikon FZ, Wafer Dummy Wafer Monitor Wafer, Wafer Ujian, wafer CZ, wafer epitaxial, wafer digilap, wafer etsa.

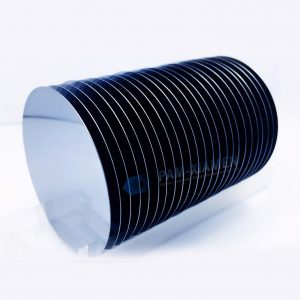

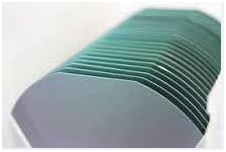

Proses pembuatan wafer silikon ialah penarikan kristal, pemotongan dadu, pengisaran, chamfering, etsa, penggilapan, pembersihan dan pemeriksaan, antaranya penarikan kristal, penggilap wafer dan pemeriksaan adalah pautan teras pembuatan wafer Si. Sebagai substrat semikonduktor asas, wafer silikon mesti mempunyai piawaian ketulenan yang tinggi, kerataan permukaan, kebersihan, dan pencemaran kekotoran untuk mengekalkan fungsi reka bentuk asal cip. Keperluan spesifikasi tinggi wafer silikon semikonduktor menjadikan proses pembuatannya rumit. Empat langkah teras termasuk penulenan polysilicon dan tuangan jongkong polisilikon, pertumbuhan wafer Si kristal tunggal, dan pemotongan dan pembentukan wafer Si. Sebagai bahan mentah untuk fab wafer, kualiti wafer silikon secara langsung menentukan kestabilan proses permohonan wafer. Wafer silikon bersaiz besar telah menjadi trend pembangunan masa depan wafer silikon. Untuk meningkatkan kecekapan pengeluaran dan mengurangkan kos, semakin banyak wafer silikon bersaiz besar digunakan.

-

12 "Perdana Gred Silicon Wafer

PAM-XIAMEN menawarkan wafer silikon telanjang 300mm (12 inci) dalam kelas prima, jenis n atau jenis p, dan ketebalan wafer silikon 300mm adalah 775 ± 15. Berbanding dengan pembekal wafer silikon lain, harga silikon wafer Powerway Wafer lebih kompetitif dengan kualiti yang lebih tinggi. Wafer silikon 300mm mempunyai hasil yang lebih tinggi per wafer daripada wafer silikon berdiameter besar.

-

12 "Silicon wafer 300mm TOX (Si Thermal Oxidation Wafer)

PAM-XIAMEN menawarkan wafer silikon oksida 300mm dan wafer dioksida. Wafer silikon oksida termal atau wafer silikon dioksida adalah wafer silikon telanjang dengan lapisan oksida yang ditanam oleh proses pengoksidaan kering atau basah. Lapisan oksida termal wafer silikon biasanya ditanam dalam relau tiub mendatar, dan julat suhu oksida wafer silikon pada umumnya 900 1200 ~ 1200 ℃. Berbanding dengan lapisan oksida CVD, lapisan oksida silikon wafer mempunyai keseragaman yang lebih tinggi, kekompakan yang lebih baik, kekuatan dielektrik yang lebih tinggi dan kualiti yang lebih baik.

-

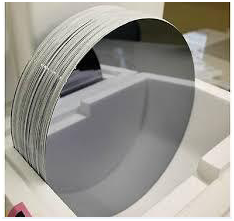

12 "Ujian Gred Silicon Wafer

PAM-XIAMEN menawarkan wafer silikon telanjang 300 mm (12 inci), kelas ujian, jenis n atau jenis p. Berbanding dengan pembekal wafer silikon yang lain, Powerway Wafer menawarkan perkhidmatan profesional dengan harga yang kompetitif.

-

Terapung-Zone Mono-Kristal Silicon

PAM-XIAMEN boleh menawarkan wafer silikon zon terapung, yang diperoleh melalui kaedah Zon Terapung. Rod silikon monohablur diperolehi melalui pertumbuhan zon terapung, dan kemudian memproses rod silikon monohablur menjadi wafer silikon, dipanggil wafer silikon zon terapung. Oleh kerana wafer silikon cair zon tidak bersentuhan dengan pijar kuarza semasa proses silikon zon terapung, bahan silikon berada dalam keadaan terampai. Oleh itu, ia kurang tercemar semasa proses lebur zon terapung silikon. Kandungan karbon dan kandungan oksigen lebih rendah, kekotoran kurang, dan kerintangan lebih tinggi. Ia sesuai untuk pembuatan peranti kuasa dan peranti elektronik voltan tinggi tertentu.

-

Ujian Wafer Monitor Wafer Dummy Wafer

Sebagai pengeluar wafer dummy, PAM-XIAMEN menawarkan wafer dummy silikon / wafer ujian / wafer monitor, yang digunakan dalam peranti pengeluaran untuk meningkatkan keselamatan pada permulaan proses pengeluaran dan digunakan untuk semakan penghantaran dan penilaian borang proses. Oleh kerana wafer silikon tiruan sering digunakan untuk eksperimen dan ujian, saiz dan ketebalannya adalah faktor penting dalam kebanyakan keadaan. Wafer tiruan 100mm, 150mm, 200mm atau 300mm tersedia.

-

Cz Mono-Kristal Silicon

PAM-XIAMEN, pengeluar silikon pukal monohablur, boleh menawarkan wafer silikon monohablur <100>, <110> dan <111> dengan dopan N&P dalam 76.2~200 mm, yang ditanam dengan kaedah CZ. Kaedah Czochralski ialah kaedah pertumbuhan kristal, dirujuk sebagai kaedah CZ. Ia disepadukan dalam sistem haba tiub lurus, dipanaskan oleh rintangan grafit, mencairkan polysilicon yang terkandung dalam mangkuk kuarza ketulenan tinggi, dan kemudian memasukkan kristal benih ke dalam permukaan cair untuk kimpalan. Selepas itu, kristal benih yang berputar diturunkan dan cair. Badan disusup dan disentuh, secara beransur-ansur dinaikkan, dan selesai atau ditarik melalui langkah-langkah menekuk, menekuk, memikul, kawalan diameter yang sama, dan kemasan.

-

Epitaxial Silicon Wafer

Silicon Epitaxial Wafer (Epi Wafer) adalah lapisan kristal silikon epitaxial tunggal yang disimpan ke wafer silikon kristal tunggal (nota: ia tersedia untuk menumbuhkan lapisan lapisan silikon poli kristal di atas wafer silikon kristal Singly yang sangat doped, tetapi ia memerlukan lapisan penyangga (seperti oksida atau poli-Si) di antara substrat Si pukal dan lapisan silikon epitaxial atas. Ia juga boleh digunakan untuk transistor filem nipis.

-

Wafer digilap

PAM-XIAMEN dapat menawarkan wafer yang digilap, jenis n atau jenis p dengan orientasi pada <100>, <110> atau <111>. Wafer digilap FZ, terutamanya untuk pengeluaran penerus silikon (SR), penerus terkawal silikon (SCR), Transistor Giant (GTR), thyristor (GRO)

-

punaran Wafer

Wafer silikon etsa yang ditawarkan oleh PAM-XIAMEN adalah wafer etsa jenis N atau P, yang mempunyai kekasaran rendah, daya kilas rendah dan daya kilas tinggi. Wafer etsa mempunyai ciri-ciri kekasaran rendah, glossiness yang baik dan kos yang agak rendah, dan secara langsung menggantikan wafer yang digilap atau wafer epitaxial yang mempunyai kos yang agak tinggi untuk menghasilkan elemen elektronik di beberapa bidang, mengurangkan kos.