GaSb вафельные

PAM-XIAMEN предлагает составные полупроводниковые пластины GaSb — антимонид галлия, выращенные LEC (Liquid Encapsulated Czochralski) как готовые к эпиляции или механические сорта с n-типом, p-типом или полуизолирующие в различной ориентации (111) или (100).

- Описание

Описание продукта

PAM-XIAMEN предлагает пластину Compound Semiconductor GaSb –антимонид галлийвыращенный LEC (жидко инкапсулированный Чохральский), который может уменьшить дефекты антимонида галлия. Пластина GaSb готова к эпиляции или механическому классу n-типа, p-типа или полуизолирующей в различной ориентации (111) или (100).

Антимонид галлия (GaSb) — полупроводниковое соединение галлия и сурьмы III-V семейства. Он имеет постоянную решетки около 0,61 нм. Пластины GaSb можно использовать для инфракрасных детекторов, инфракрасных светодиодов, лазеров и транзисторов, а также термофотоэлектрических систем.

Вот подробная спецификация пластины:

2 "(50,8) Спецификация GaSb вафельные

3 "(50,8) Спецификация GaSb вафельные

4 "(100 мм) Спецификация GaSb вафельные

2″ Спецификация пластины GaSb

| ТЕМ | Технические характеристики | ||

| добавка | низколегированный | цинк | Теллур |

| Тип проводимости | Р-типа | Р-типа | N-типа |

| Диаметр пластины | 2 " | ||

| Ориентация пластины | (100) ± 0,5 ° | ||

| Толщина пластины | 500 ± 25 мкм | ||

| Основная плоская длина | 16 ± 2 мм | ||

| Вторичная плоская длина | 8 ± 1 мм | ||

| Концентрация носителя | (1-2)х1017см-3 | (5-100)х1017см-3 | (1-20)х1017см-3 |

| Мобильность | 600-700см2/Вс | 200-500см2/Вс | 2000-3500см2/Вс |

| EPD | <2 × 103 см-2 | ||

| TTV | <10um | ||

| ЛУК | <10um | ||

| WARP | <12 мкм | ||

| Лазерная маркировка | по требованию | ||

| Отделка поверхности | Р / Е, Р / Р | ||

| Эпи Готов | да | ||

| Пакет | Одиночный вафельный контейнер или кассета | ||

3″ Спецификация пластины GaSb

| ТЕМ | Технические характеристики | ||

| Тип проводимости | Р-типа | Р-типа | N-типа |

| добавка | низколегированный | цинк | Теллур |

| Диаметр пластины | 3 " | ||

| Ориентация пластины | (100) ± 0,5 ° | ||

| Толщина пластины | 600 ± 25 мкм | ||

| Основная плоская длина | 22 ± 2 мм | ||

| Вторичная плоская длина | 11 ± 1 мм | ||

| Концентрация носителя | (1-2)х1017см-3 | (5-100)х1017см-3 | (1-20)х1017см-3 |

| Мобильность | 600-700см2/Вс | 200-500см2/Вс | 2000-3500см2/Вс |

| EPD | <2 × 103 см-2 | ||

| TTV | <12 мкм | ||

| ЛУК | <12 мкм | ||

| WARP | <15 мкм | ||

| Лазерная маркировка | по требованию | ||

| Отделка поверхности | Р / Е, Р / Р | ||

| Эпи готов | да | ||

| Пакет | Одиночный вафельный контейнер или кассета | ||

Спецификация 4-дюймовой пластины GaSb

| ТЕМ | Технические характеристики | ||

| добавка | низколегированный | цинк | Теллур |

| Тип проводимости | Р-типа | Р-типа | N-типа |

| Диаметр пластины | 4 " | ||

| Ориентация пластины | (100) ± 0,5 ° | ||

| Толщина пластины | 800 ± 25 мкм | ||

| Основная плоская длина | 32,5 ± 2,5 мм | ||

| Вторичная плоская длина | 18 ± 1 мм | ||

| Концентрация носителя | (1-2)х1017см-3 | (5-100)х1017см-3 | (1-20)х1017см-3 |

| Мобильность | 600-700см2/Вс | 200-500см2/Вс | 2000-3500см2/Вс |

| EPD | <2 × 103 см-2 | ||

| TTV | <15 мкм | ||

| ЛУК | <15 мкм | ||

| WARP | <20 мкм | ||

| Лазерная маркировка | по требованию | ||

| Отделка поверхности | Р / Е, Р / Р | ||

| Эпи готов | да | ||

| Пакет | Одиночный вафельный контейнер или кассета | ||

1) 2 "(50,8), 3" (76,2 мм) GaSb пластины

Ориентация: (100) ± 0,5 °

Толщина (мкм): 500±25; 600±25

Тип/легирующая добавка:P/низколегированная;P/Si;P/Zn

Nc(см-3):(1~2)E17

Мобильность (см2/В·с): 600~700

Метод роста: CZ

Польский:SSP

2) 2 "(50,8) GaSb пластины

Ориентация: (100) ± 0,5 °

Толщина (мкм): 500±25; 600±25

Тип/легирующая добавка: N/низколегированная; P/Te

Nc(см-3):(1~5)E17

Мобильность (см2/В·с): 2500~3500

Метод роста: LEC

Польский:SSP

3) 2 "(50,8) GaSb пластины

Ориентация: (111)А±0,5°

Толщина (мкм): 500±25

Тип/легирующая добавка: N/Te; P/Zn

Nc(см-3):(1~5)E17

Мобильность (см2/В·с): 2500~3500;200~500

Метод роста: LEC

Польский:SSP

4) 2 "(50,8) GaSb пластины

Ориентация:(111)В±0,5°

Толщина (мкм): 500±25; 450±25

Тип/легирующая добавка: N/Te; P/Zn

Nc(см-3):(1~5)E17

Мобильность (см2/В·с): 2500~3500;200~500

Метод роста: LEC

Польский:SSP

5) 2 "(50,8) GaSb пластины

Ориентация:(111)B 2град.выкл.

Толщина (мкм): 500±25

Тип/легирующая добавка: N/Te; P/Zn

Nc(см-3):(1~5)E17

Мобильность (см2/В·с): 2500~3500;200~500

Метод роста: LEC

Польский:SSP

Относительные продукты:

InAs вафельные

InSb вафельные

InP пластины

GaAs вафельные

GaSb вафельные

GaP вафельные

Галлий антимонида (GaSb) может поставляться в виде пластин с вырезом в виде, протравленной или полированной отделкой и доступны в широком диапазоне концентрации носителей, диаметр и толщины.

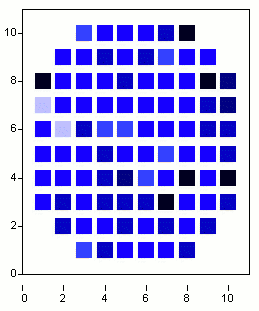

Материал GaSb обладает интересными свойствами антимонида галлия для однопереходных термофотоэлектрических (TPV) устройств. Представлен монокристалл GaSb:Te, выращенный методом Чохральского (Cz) или модифицированным методом Чохральского (Mo-Cz), и обсуждается проблема однородности Te. Поскольку подвижность носителей является одним из ключевых моментов для кристаллов антимонида галлия, проведены холловские измерения. Здесь мы представляем некоторые дополнительные разработки, основанные на технологии обработки материалов: выращивание объемных кристаллов антимонида галлия, подготовку пластин антимонида галлия и травление пластин антимонида галлия. Последующие шаги после них связаны с проработкой p/no rn/p перехода. Представлены некоторые результаты, полученные для различных подходов к разработке тонкого слоя. Таким образом, от простого процесса диффузии из паровой фазы или процесса жидкофазной эпитаксии до процесса химического осаждения металлоорганических соединений из паровой фазы мы сообщаем о некоторой специфичности материала.

Мы также предлагаем услуги эпиляции пластин антимонида галлия, в качестве примера рассмотрим ниже:

2-дюймовая эпиграфическая пластина GaSb:

Эпи-слой: толщина 0,5 мкм, нелегированный эпи-слой GaSb p-типа (также доступен нелегированный эпи-слой InP),

Подложка: 2-дюймовый полуизолирующий GaAs.

Примечание:

Правительство Китая объявило о новых ограничениях на экспорт галлиевых материалов (таких как GaAs, GaN, Ga2O3, GaP, InGaAs и GaSb) и германиевых материалов, используемых для изготовления полупроводниковых микросхем. С 1 августа 2023 года экспорт этих материалов разрешен только при наличии лицензии Министерства торговли Китая. Надеемся на ваше понимание и сотрудничество!

Дополнительную информацию об эпивафлях читайте: