Carbon neutrality refers to through afforestation, energy saving and emission reduction, etc., to offset the carbon dioxide or greenhouse gas emissions generated by itself, to achieve positive and negative offset, to achieve relatively “zero emissions”. Only by reducing energy consumption can carbon emissions be reduced, and the wide-bandgap semiconductors represented by silicon carbide (SiC) and gallium nitride (GaN) are playing this role! As a manufacturer of semiconductor materials, PAM-XIAMEN always aims to provide high-performance SiC wafer and GaN wafer for your carbon neutral solutions.

1. SiC & GaN Wafers Begin Large-Scale Applications

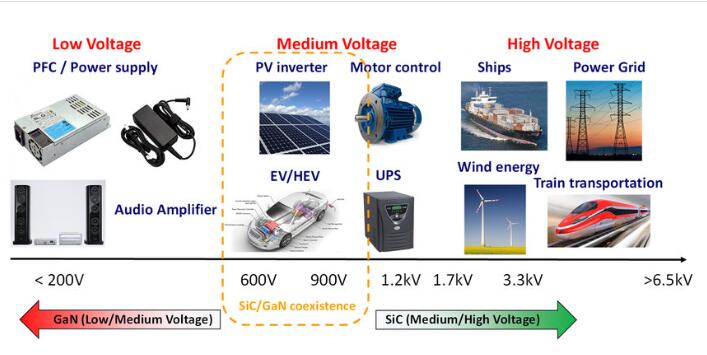

Carbon neutrality has triggered changes in the power system and industrial structure, which not only promoted the development of emerging industries such as new energy vehicles, but also proposed higher energy efficiency indicators for high-energy-consuming scenarios such as data centers, and promote the intelligent transformation of traditional fields such as rail transit. These new trends will open up considerable incremental markets for SiC and GaN semiconductors. So there is expansion capacity for SiC and GaN semiconductor wafers in the power generation, power transmission and transformation, and power consumption involved in carbon neutrality. The key areas include electric vehicles, charging piles, photovoltaic and wind power conversion, and electronic product chargers.

SiC & GaN Applications

1.1 In Terms of SiC Material

Reducing carbon emissions in the automotive industry is an important part of achieving the carbon neutral. New energy vehicles with obvious carbon reduction effects will usher in a broader application space. SiC semiconductor materials can provide motor controllers with higher energy conversion rate, smaller volume and lighter weight for new energy vehicles, thereby reducing the weight of the whole vehicle and reducing energy consumption.

After Tesla pioneered, more and more car companies are equipped with or plan to use silicon carbide modules in electric models. Yole predicts that by 2025, the silicon carbide market size in the field of new energy vehicles and charging piles will reach US$1.778 billion, accounting for about 70% of the total silicon carbide market size.

Rail transit is moving from mechanical brake control to digital control, and silicon carbide can provide more stable and controllable electronic core devices for rail transit. Silicon carbide power devices have been applied and verified in traction inverters for rail transit, and have broad application potential.

1.2 In Terms of GaN Material

The emergence of big data, cloud services, and artificial intelligence has driven the continuous growth of the processing capacity of data centers around the world, and the number of server deployments has increased accordingly. According to IDC statistics, global server shipments will reach 12.2 million units in 2020. GaN-based server power supplies can more efficiently contribute to the energy-saving goals of data centers. On the one hand, GaN can reduce the power consumption and heat consumption of server power supplies. On the other hand, the production of GaN devices requires fewer parts than silicon devices, which can reduce the carbon emissions required to produce parts. According to data reported, the use of gallium nitride can save about 1.9 billion US dollars in electricity bills for global data centers every year.

GaN wafers are also useful in approaching consumer power consumption. At present, mobile phone manufacturers have launched GaN fast charging to provide consumers with a faster and more efficient charging experience while reducing the size of the charger. At the same time, in solar scenarios, GaN-based solar inverters can achieve a smaller volume and even be placed at home by consumers, allowing consumers to get environmental-friendly and cost-effective electricity, which is helpful for the goal of carbon neutrality.

2. Improving SiC, GaN Technology & Product Maturity for Energy Efficient

Although the application prospect of wide-bandgap semiconductors in energy conservation and emission reduction has been recognized by the industry, in order to truly play a role in the “dual carbon” strategy, it is necessary to continue to improve technical indicators and product maturity. Achieving carbon neutrality more effectively requires optimizing energy efficiency and reducing energy consumption. Silicon carbide should further reduce forward voltage drop to reduce losses. Gallium nitride needs to improve product stability and consistency.

Specifically, voltage and frequency are the keys to the performance improvement and application expansion of wide-bandgap semiconductors. Taking GaN as an example, the increase in the upper voltage limit will expand the application field of GaN. The increase in the upper frequency limit will accelerate the standardization and industrialization of GaN products.

In the future, the voltage of the battery system of electric vehicles will be increased from the current 400V to 800V, and the voltage of GaN devices will be increased from 650V to 1200V, which can meet the needs of electric vehicles. At the same time, the increase in the upper limit of the frequency of GaN will promote the change of the power supply form, make the modularization and standardization of GaN power supply possible, and realize the increase of production capacity and the reduction of cost, which will bring more possibilities for the development of GaN.

For more information, please contact us email at victorchan@powerwaywafer.com and powerwaymaterial@gmail.com.