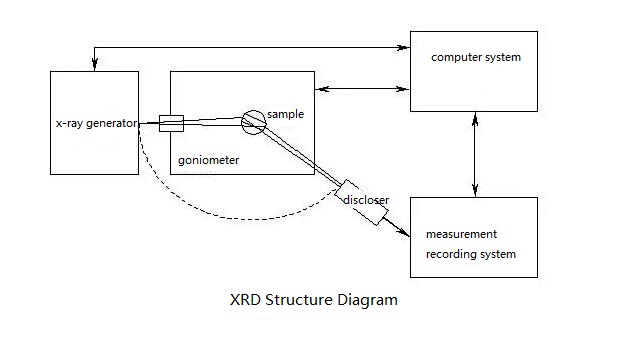

We can offer semiconductor wafers with X-ray diffraction (XRD) diagram. So what is XRD? XRD technology is a research method to obtain information such as the composition of the material, the structure or morphology of the atoms or molecules in the material by analyzing the diffraction pattern of the material by X-ray diffraction. XRD analysis is the main method to study the phase and crystal structure of substances. When a substance (crystalline or amorphous) is subjected to diffraction analysis, the substance is irradiated by X-rays to produce different degrees of diffraction. Substance composition, crystal form, intermolecular bonding mode, molecular configuration, conformation, etc. determine the unique diffraction pattern of the substance. The X-ray diffraction method has the advantages of no damage to the sample, no pollution, rapidity, high measurement accuracy, and a large amount of information about the crystal integrity can be obtained. Therefore, X-ray diffraction analysis, as a modern scientific method of material structure and composition analysis, has gradually been widely used in research and production of various disciplines. Below is the structure of X-ray diffractometers and goniometers:

Fig. 1 Structure of X-ray Diffractometers and Goniometers

1. Basic Principle of XRD

The basic principle of X-ray diffraction is that when introducing a beam of monochromatic X-rays on a crystal composed of a unit cell with atoms regularly arranged, the distance between the atoms and the wavelength of the incident X-ray are in the same order of magnitude. Therefore, different atomic scattering X-ray will interact. Interference will generate strong X-ray diffraction in special directions. Crystal structure has a significant impact on the orientation and intensity of X-ray diffraction in spatial distribution.

According to its principle, the most important characteristics of the diffraction pattern of a crystal are:

* The distribution law of diffraction lines in space;

* The intensity of the diffracted beam.

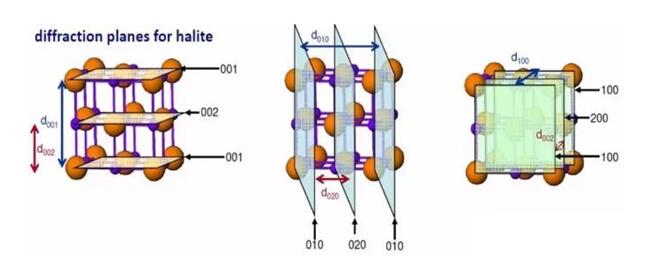

Among them, the distribution law of diffraction lines is determined by the size, shape and orientation of the unit cell, and the intensity of diffraction lines depends on the species of atoms and their positions in the unit cell. Therefore, different crystals have different diffraction patterns, shown as figure as follows:

Fig. 2 Different Crystals with Different Diffraction Patterns

2. Applications of X-Ray Diffraction

X-ray diffraction technology has become the most basic and important material structure characterization method, and its application range is also very broad, covering various fields such as physics, chemistry, geology, life science, engineering and materials. Below we briefly list several aspects of its main applications:

2.1 Phase Analysis

Phase analysis is the most widely used direction of X-ray diffraction in material analysis, and it is one of the preliminary analysis work of material research. Phase analysis includes qualitative analysis and quantitative analysis. Qualitative analysis is to compare the measured interplanar spacing and diffraction intensity of the material with the diffraction data of the standard phase to determine the phase present in the material; the latter is based on the position and intensity of diffraction peaks in the diffraction data to determine the content of each phase in the material.

2.2 Determination of Crystallinity

Crystallinity directly affects the properties of materials, so the determination of crystallinity is particularly important. X-ray diffraction is a relatively simple and quick determination method. This method measures the total scattering intensity, which is the sum of the scattering intensities of matter in the entire space, and is only related to the intensity of the primary ray, chemical structure, and the total number of electrons participating in the diffraction, that is, the mass, and has nothing to do with the order of the sample. Therefore, if crystalline scattering and amorphous scattering can be separated from the diffractogram, the degree of crystallinity is the ratio of the crystalline partial scattering to the total scattering intensity.

2.3 Precise Determination of Lattice Parameters

Precise determination of lattice parameters is often used in the determination of solid-state solubility curves of phase diagrams. The change of solubility often causes the change of lattice constant. When the solubility limit is reached, the continuous increase of solute causes the precipitation of new phase, and no longer causes the change of lattice constant. This turning point is the dissolution limit. In addition, the precise determination of the lattice constant can obtain the number of atoms per unit cell, thereby determining the type of solid solution; it can also calculate useful physical constants such as density and expansion coefficient.

In addition, X-ray diffraction can also be used for testing and analysis of structural phase transition, epitaxial wafer strain state, grain size, structural distortion, film thickness, material density, organizational structure, residual stress, etc.

For more information, please contact us email at victorchan@powerwaywafer.com and powerwaymaterial@gmail.com.