PAM-XIAMEN menawarkan Gallium Nitride wafer substrat untuk UHB-LED, Gallium Nitride wafer, LD dan peranti semikonduktor lain.

SiC Wafer

Silikon Carbideï¼SiC) Wafers PAM-XIAMENÂ menawarkan Silicon Carbide wafer crytal dan epitaxy, yang digunakan untuk Optoelektronik Devices, Devices kuasa tinggi, Peranti Suhu Tinggi, High Frequency Devices Power

GaAs Wafer

PAM-XIAMEN menawarkan galium arsenida wafer substrat dan epitaxy untuk LED, LD dan aplikasi Microelectronics

kompaun Semiconductor

PAM-XIAMEN menawarkan Indium Semiconductor Wafer: INSB, InP, Inas, GASB, Jurang

Germanium Wafer

PWAMÂ menawarkan bahan semikonduktor, (Ge) kristal Single Germanium dan Wafers berkembang dengan VGF / LEC

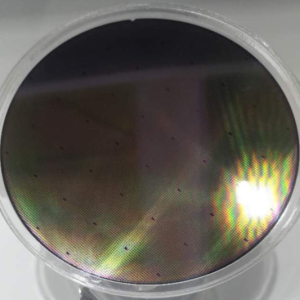

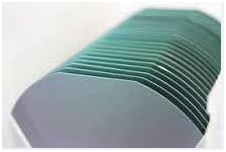

Silicon Wafer

PAM-XIAMEN, syarikat pembuatan wafer silikon, menawarkan wafer silikon: Wafer silikon FZ, Wafer Uji Monitor Wafer Wafer Dummy, Wafer Uji, wafer CZ, wafer epitaxial, wafer digilap, wafer pengukir.

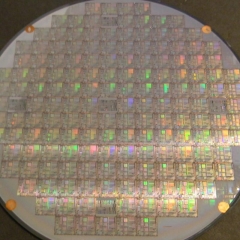

Proses pembuatan wafer silikon adalah penarik kristal, pencetakan wafer silikon, pengisaran wafer silikon, penggerudian, pengukiran, penggilap, pembersihan dan pemeriksaan, di antaranya penarikan kristal, penggilap dan pemeriksaan wafer silikon adalah penghubung inti pembuatan wafer silikon. Sebagai substrat semikonduktor asas, wafer silikon mesti mempunyai standard ketulenan, kerataan permukaan, kebersihan, dan pencemaran kotoran yang tinggi untuk mengekalkan fungsi cip yang dirancang asal. Keperluan spesifikasi tinggi wafer silikon semikonduktor menjadikan proses pembuatannya rumit. Empat langkah teras merangkumi pemurnian polisilikon dan pemutus ingot polisilikon, pertumbuhan wafer silikon kristal tunggal, dan pemotongan dan pembentukan wafer silikon. Sebagai bahan mentah untuk wafer fab, kualiti wafer silikon secara langsung menentukan kestabilan proses aplikasi wafer silikon. Wafer silikon bersaiz besar telah menjadi trend pengembangan wafer silikon pada masa hadapan. Untuk meningkatkan kecekapan pengeluaran dan mengurangkan kos, semakin banyak wafer silikon bersaiz besar digunakan.

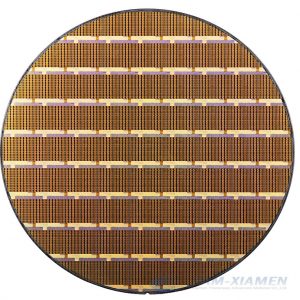

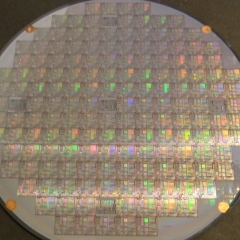

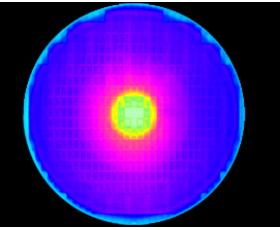

WAFER FABRICATION

PAM-XIAMEN Tawaran plat photoresist dengan photoresist dan photomask, dan menyediakan Nanolithography (photolithography): Penyediaan permukaan, photoresist memohon, bakar Lembut, Alignment, Pendedahan, Pembangunan, Hard bakar, Bangunkan memeriksa, Etch, photoresist penyingkiran (jalur), pemeriksaan Akhir.

-

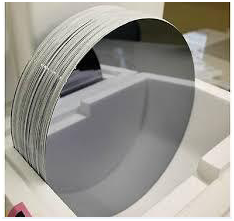

12 "Perdana Gred Silicon Wafer

PAM-XIAMEN menawarkan wafer silikon telanjang 300mm (12 inci) dalam kelas prima, jenis n atau jenis p, dan ketebalan wafer silikon 300mm adalah 775 ± 15. Berbanding dengan pembekal wafer silikon lain, harga silikon wafer Powerway Wafer lebih kompetitif dengan kualiti yang lebih tinggi. Wafer silikon 300mm mempunyai hasil yang lebih tinggi per wafer daripada wafer silikon berdiameter besar.

-

12 "Silicon wafer 300mm TOX (Si Thermal Oxidation Wafer)

PAM-XIAMEN menawarkan wafer silikon oksida 300mm dan wafer dioksida. Wafer silikon oksida termal atau wafer silikon dioksida adalah wafer silikon telanjang dengan lapisan oksida yang ditanam oleh proses pengoksidaan kering atau basah. Lapisan oksida termal wafer silikon biasanya ditanam dalam relau tiub mendatar, dan julat suhu oksida wafer silikon pada umumnya 900 1200 ~ 1200 ℃. Berbanding dengan lapisan oksida CVD, lapisan oksida silikon wafer mempunyai keseragaman yang lebih tinggi, kekompakan yang lebih baik, kekuatan dielektrik yang lebih tinggi dan kualiti yang lebih baik.

-

12 "Ujian Gred Silicon Wafer

PAM-XIAMEN menawarkan wafer silikon telanjang 300 mm (12 inci), kelas ujian, jenis n atau jenis p. Berbanding dengan pembekal wafer silikon yang lain, Powerway Wafer menawarkan perkhidmatan profesional dengan harga yang kompetitif.

-

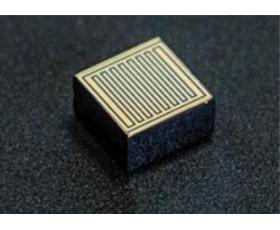

Epi Wafer untuk Laser Diod

Wafer epitaxy LD berasaskan GaAs, yang dapat menghasilkan rangsangan pelepasan, digunakan secara meluas untuk membuat dioda laser kerana sifat wafer epitaxial GaAs yang unggul menjadikan peranti ini penggunaan tenaga rendah, kecekapan tinggi, jangka hayat yang lama dan lain-lain. Selain wafer LD epi gallium arsenide , bahan semikonduktor yang biasa digunakan adalah kadmium sulfida (CdS), indium fosfida (InP), dan zink sulfida (ZnS).

-

Terapung-Zone Mono-Kristal Silicon

PAM-XIAMEN dapat menawarkan wafer silikon zon terapung, yang diperoleh dengan kaedah Float Zone. Batang silikon monokristalin dapat dicapai melalui pertumbuhan zon apungan, dan kemudian memproses batang silikon monokristalin menjadi wafer silikon, yang disebut wafer silikon zon apungan. Oleh kerana wafer silikon cair zon tidak bersentuhan dengan pelindung kuarza semasa proses silikon zon terapung, bahan silikon berada dalam keadaan terampai. Oleh itu, ia kurang tercemar semasa proses peleburan silikon zon terapung. Kandungan karbon dan oksigen lebih rendah, kekotoran lebih sedikit, dan daya tahan lebih tinggi. Ia sesuai untuk pembuatan peranti kuasa dan alat elektronik voltan tinggi tertentu.

-

Perkhidmatan Pengecoran Wafer

PAM-XIAMEN menyediakan perkhidmatan pengecoran wafer dengan teknologi proses semikonduktor yang maju dan memanfaatkan pengalaman hulu kami mengenai substrat dan wafer expaxy,

PAM-XIAMEN adalah teknologi wafer dan perkhidmatan faundri yang paling maju untuk syarikat, IDM dan penyelidik fabless.

-

Ujian Wafer Monitor Wafer Dummy Wafer

Sebagai pengeluar wafer dummy, PAM-XIAMEN menawarkan wafer dummy silikon / wafer ujian / wafer monitor, yang digunakan dalam alat produksi untuk meningkatkan keselamatan pada awal proses pengeluaran dan digunakan untuk pemeriksaan penghantaran dan penilaian bentuk proses. Oleh kerana wafer silikon palsu sering digunakan untuk eksperimen dan ujian, ukuran dan ketebalannya adalah faktor penting dalam kebanyakan keadaan. Wafer dummy 100mm, 150mm, 200mm, atau 300mm ada.

-

Cz Mono-Kristal Silicon

PAM-XIAMEN, pengeluar silikon pukal monokristalin, dapat menawarkan wafer silikon monokristal <100>, <110> dan <111> dengan dopan N&P dalam 76,2 ~ 200 mm, yang ditanam dengan kaedah CZ. Kaedah Czochralski adalah kaedah pertumbuhan kristal, disebut sebagai kaedah CZ. Ia disatukan dalam sistem haba tiub lurus, dipanaskan oleh rintangan grafit, mencairkan polysilicon yang terdapat dalam wadah kuarza dengan kemurnian tinggi, dan kemudian memasukkan kristal biji ke permukaan lebur untuk pengelasan. Selepas itu, kristal biji putar diturunkan dan dicairkan. Tubuh disusupi dan disentuh, diangkat secara beransur-ansur, dan selesai atau ditarik melalui langkah-langkah mengikat, mengikat, memeluk, mengawal diameter yang sama, dan menyelesaikan.

-

Epitaxial Silicon Wafer

Silicon Epitaxial Wafer (Epi Wafer) adalah lapisan kristal silikon epitaxial tunggal yang disimpan ke wafer silikon kristal tunggal (nota: ia tersedia untuk menumbuhkan lapisan lapisan silikon poli kristal di atas wafer silikon kristal Singly yang sangat doped, tetapi ia memerlukan lapisan penyangga (seperti oksida atau poli-Si) di antara substrat Si pukal dan lapisan silikon epitaxial atas. Ia juga boleh digunakan untuk transistor filem nipis.

-

Wafer digilap

PAM-XIAMEN dapat menawarkan wafer yang digilap, jenis n atau jenis p dengan orientasi pada <100>, <110> atau <111>. Wafer digilap FZ, terutamanya untuk pengeluaran penerus silikon (SR), penerus terkawal silikon (SCR), Transistor Giant (GTR), thyristor (GRO)

-

punaran Wafer

Wafer silikon etsa yang ditawarkan oleh PAM-XIAMEN adalah wafer etsa jenis N atau P, yang mempunyai kekasaran rendah, daya kilas rendah dan daya kilas tinggi. Wafer etsa mempunyai ciri-ciri kekasaran rendah, glossiness yang baik dan kos yang agak rendah, dan secara langsung menggantikan wafer yang digilap atau wafer epitaxial yang mempunyai kos yang agak tinggi untuk menghasilkan elemen elektronik di beberapa bidang, mengurangkan kos.

-

Fotoresis Nanofabrikasi

PAM-XIAMEN Tawaran plat photoresist dengan photoresist