PAM-XIAMEN can supply you with 4H-SiC wafers fitting your demands, specifications as found in https://www.powerwaywafer.com/sic-wafer/sic-wafer-substrate.html.

The control of a single crystal form during the growth process of SiC crystals is a complex problem, involving the selection of multiple growth parameters and the optimization of temperature field structure, and the parameters are interrelated. The main factors currently known to affect the stable growth of silicon carbide crystal form include seed crystal polarity and off-axis angle, growth temperature, supersaturation, Si/C ratio of gas-phase components, growth pressure, doping type, etc. This means that precise control of SiC crystal form becomes more difficult.

1. Influence of Growth Steps on Stability of 4H-SiC Crystal Structure

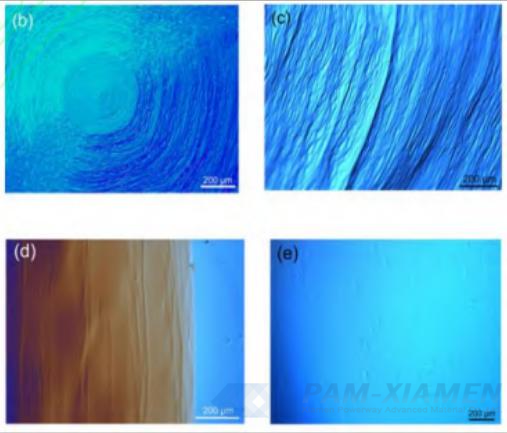

On the surface of SiC crystals grown by PVT method, spiral step growth characteristics can be clearly observed through optical microscopy, especially in the region near small planes, as shown in Fig. 1. Usually, the closer it is to a small flat area, the wider the width of the plane between its steps. However, as it moves away from the small flat area, the width of the steps gradually decreases or even disappears, which is mainly related to the angle between the tangent lines at different positions and the small plane. During the growth process of silicon carbide crystals, the growth steps formed on the surface of the seed crystals help maintain the nucleation and development of a single crystal form.

Fig. 1 Optical image of N doped 4H SiC surface

Guo et al. observed that although there may be a phase transition behavior during crystal growth, the small planar region consistently maintains a single crystal growth of 4H SiC, due to the step growth mode maintained throughout the region. The formation of surface steps can promote the nucleation and growth of gas-phase atoms along the steps or kinks, strictly inheriting the existing stacking information of the growth steps, and thus easily maintaining single crystal growth. In addition to providing growth steps, the width of the plane between the steps is also a key factor affecting the stable growth of the crystal form.

Liu et al. pointed out that when the width of the plane between the growth steps is smaller than the diffusion distance of gas-phase atoms, the gas-phase atoms smoothly enter the step or twist through adsorption and diffusion processes and inherit the stacking order of the inherent crystal form, in order to achieve the goal of stable crystal form. On the contrary, when the atomic diffusion distance is much smaller than the plane width, gas phase atoms are prone to aggregation and form two-dimensional nucleation on the plane, resulting in 15R or 6H polytype inclusions. It can be inferred that the prerequisite for maintaining the growth of a single crystal form of silicon carbide is the formation of surface steps, and the key lies in controlling the plane width between the steps. The use of off-axis seed crystals and the introduction of doping can effectively reduce the plane width between steps, suppress step aggregation behavior, and help achieve stable crystal growth.

2. Influence of Doping Types on Stability of 4H-SiC Crystal Structure

It is usually necessary to prepare SiC single crystal substrates with low resistivity in order to reduce power loss caused by parasitic substrates and contact resistance, and to ensure the reliability of SiC devices. Nitrogen (N) doping as a shallow donor impurity can effectively improve the electrical properties of n-type SiC substrates by occupying the C lattice. Although the theoretical nitrogen doping concentration can reach 5×1020 cm-3, corresponding to a crystal resistivity of 0.005 Ω·cm, the current commercial n-type 4H SiC single crystal substrates mainly have a resistivity range of 0.015~0.025 Ω·cm, corresponding to N doping concentration of 6×1018~1.5×1019 cm-3. This is because heavy doping (≥ 1020 atoms/cm3) can generate significant stacking faults, which in turn alter the crystal structure and generate various electron capture defects, and even lead to 3C polytype inclusions. In addition to improving the conductivity of SiC substrates, N doping has also been proven to be useful for stabilizing the growth of 4H SiC crystal forms.

Nishizawa et al. investigated the effect of N doping on the stability of 4H-SiC crystal form using density functional theory (DFT). The results indicate that doping can significantly expand the stacking energy difference between different crystal forms, and under N doping, the stacking energy difference on the C plane (E6H-E4H) and (E3C-E4H) is much greater than 0, indicating that the 4H-SiC crystal form will preferentially nucleate and grow. Schmitt et al. provided three possible explanations for the mechanism of N-doped stable 4H crystal structure:

1) N doping promotes the increase of C-containing components in the gas phase at the front of the growth interface and reduces the Si/C ratio by occupying the C lattice on the SiC lattice;

2) The reaction between nitrogen and solid carbon forms C2N2 and further enhances the transport capacity of C;

3) A higher nitrogen content in the gas phase helps to suppress step aggregation and reduce the plane width between macroscopic steps.

It can be seen that N doping indeed contributes to the stable growth of 4H SiC crystal form, and the doping effect is also related to the growth temperature. But the control of doping concentration is also crucial, otherwise it will lead to an increase in dislocation density within the crystal and induce the generation of 3C SiC multi type inclusions. Therefore, when selecting doping concentration, it is necessary to balance the relationship between crystal stability and defect density. Rost et al. pointed out that when the doping concentration is greater than 2×1019cm-3, double Shockley stacking faults will occur in the 4H SiC crystal form. It is recommended that the doping concentration be lower than 2×1019 cm-3.

On the contrary, for Al doped systems, 4H SiC tends to grow more on the seed Si surface. This indicates that the selection of seed crystal polarity needs to match the doping type. In addition to the N and Al doping mentioned above, Ce doping has also been proven to have a positive effect on stabilizing the 4H SiC crystal structure.

Sejak Itoh et al. pertama kali dicadangkan pada tahun 1994 bahawa doping Ce boleh membantu menstabilkan struktur kristal 4H SiC, hasil penyelidikan berkaitan telah dilaporkan berturut-turut. Pada tahun 2010, Tymicki et al. memperkenalkan doping Ce ke dalam kristal 4H SiC yang ditanam melalui kaedah PVT, dengan CeO2 sebagai sumber serium. Keputusan menunjukkan bahawa doping Ce bukan sahaja boleh menggalakkan pertumbuhan stabil bentuk kristal 4H SiC, tetapi juga menyekat kakisan pada bahagian belakang kristal benih dan meningkatkan hasil kristal tunggal. Tambahan pula, Racka et al. menggunakan CeSi2 sebagai sumber serium untuk mengembangkan kristal 4H SiC secara stabil pada satah kristal 6H SiC, dan menerangkan perbezaan utama antara dua sumber serium (CeO2 dan CeSi2) semasa proses pertumbuhan. Iaitu, berbanding dengan CeO2, menggunakan CeSi2 sebagai sumber serium di bawah keadaan penyediaan yang sama membantu untuk mendapatkan kristal silikon karbida dengan kerintangan elektrik yang lebih rendah. Malangnya, tiada seorang pun daripada mereka telah memberikan alasan untuk doping Ce untuk menyekat kecacatan kemasukan pelbagai jenis. Pada tahun 2022, Racka Szmidt et al. memberikan penjelasan yang mungkin, menunjukkan bahawa Ce dalam fasa gas boleh meningkatkan keupayaan N untuk memasuki kekisi SiC, dengan itu meningkatkan nisbah C/Si dalam komponen fasa gas di hadapan antara muka pertumbuhan. Ini jelas berfaedah untuk menstabilkan bentuk kristal 4H SiC dan kepekatan doping optimum ialah 0.5 wt%. Jika kepekatan doping ditingkatkan lagi (1 wt%), ia sebaliknya akan mendorong kemasukan polimorfik.

3. Pengaruh Faktor Lain Terhadap Kestabilan Politaip 4H-SiC

Sebagai tambahan kepada pelbagai faktor yang dinyatakan di atas, parameter seperti kadar pertumbuhan kristal, tekanan pertumbuhan, kadar penyahtekanan, dan supersaturasi hadapan antara muka juga mempengaruhi kestabilan struktur kristal 4H-SiC kepada darjah yang berbeza-beza. Kakimoto et al. menjalankan simulasi global peringkat nukleasi awal 4H-SiC yang ditanam melalui kaedah PVT berdasarkan teori nukleasi termodinamik klasik. Didapati bahawa perbezaan tenaga bebas yang diperlukan untuk nukleasi bentuk kristal 4H dan 6H SiC berkorelasi positif dengan tekanan pertumbuhan. Meningkatkan tekanan pertumbuhan boleh meningkatkan perbezaan tenaga nukleasi antara kedua-dua bentuk kristal, dengan itu mencapai pertumbuhan satu bentuk kristal 4H SiC. Walau bagaimanapun, tekanan yang berlebihan jelas menghalang pertumbuhan kristal.

Tambahan pula, walaupun supersaturasi yang diperlukan untuk pertumbuhan kristal 4H-SiC adalah agak tinggi, ia tidak semestinya lebih baik untuk mempunyai supersaturasi yang lebih tinggi. Yang et al. menegaskan bahawa supersaturasi yang berlebihan semasa proses pertumbuhan bentuk kristal 4H-SiC sebenarnya boleh mendorong kemasukan politaip dalam 6H dan 15R SiC, terutamanya di tepi kristal. Ini kerana perbezaan tenaga bebas nukleasi antara bentuk hablur yang berbeza adalah minimum di pinggir hablur benih, dan supersaturasi yang lebih rendah membantu meningkatkan perbezaan dalam tenaga nukleasi antara bentuk hablur 4H dan 6H SiC, dengan itu menstabilkan pertumbuhan 4H SiC.

Mekanisme nukleasi dua dimensi boleh digunakan untuk menerangkan sebab-sebab pembentukan kecacatan kemasukan pelbagai jenis yang disebabkan oleh supersaturasi yang berlebihan. Apabila tahap supertepu yang tinggi terbentuk di hadapan antara muka pertumbuhan, bahan fasa gas yang terjerap pada satah pertumbuhan tidak mempunyai masa untuk berhijrah ke langkah atau twist, menyebabkan pengagregatan bersama antara atom dan nukleasi dan pertumbuhan selanjutnya, membentuk pulau terpencil dan mendorong kemasukan pelbagai jenis. Ini secara tidak langsung menunjukkan bahawa kadar pertumbuhan yang terlalu cepat jelas memudaratkan penyediaan satu bentuk kristal SiC.

Secara keseluruhannya, struktur hablur 4H-SiC cenderung berkembang dalam persekitaran berikut: menggunakan permukaan hablur benih 4H SiC luar paksi sebagai permukaan pertumbuhan, melaraskan tekanan rongga dan suhu pertumbuhan untuk membentuk nisbah C/Si yang lebih tinggi dan supertepu yang lebih besar. di hadapan antara muka pertumbuhan. Pada masa yang sama, unsur-unsur doped serium dan nitrogen masing-masing dimasukkan ke dalam serbuk polihabluran dan komponen fasa gas, dan kestabilan medan suhu dan aliran udara berhampiran antara muka pertumbuhan dikekalkan sebanyak mungkin sepanjang keseluruhan kitaran pertumbuhan. Untuk mendapatkan pemahaman yang lebih mendalam tentang faktor dan mekanisme tindak balas yang mendorong kecacatan kemasukan pelbagai jenis, perbincangan dan analisis lanjut telah dijalankan ke atas parameter utama utama dari perspektif termodinamik dan kinetik.

Untuk maklumat lanjut, sila hubungi kami e-mel divictorchan@powerwaywafer.com dan powerwaymaterial@gmail.com.