PAM-XIAMEN can supply you with 4H-SiC wafers fitting your demands, specifications as found in https://www.powerwaywafer.com/sic-wafer/sic-wafer-substrate.html.

The control of a single crystal form during the growth process of SiC crystals is a complex problem, involving the selection of multiple growth parameters and the optimization of temperature field structure, and the parameters are interrelated. The main factors currently known to affect the stable growth of silicon carbide crystal form include seed crystal polarity and off-axis angle, growth temperature, supersaturation, Si/C ratio of gas-phase components, growth pressure, doping type, etc. This means that precise control of SiC crystal form becomes more difficult.

1. Influence of Growth Steps on Stability of 4H-SiC Crystal Structure

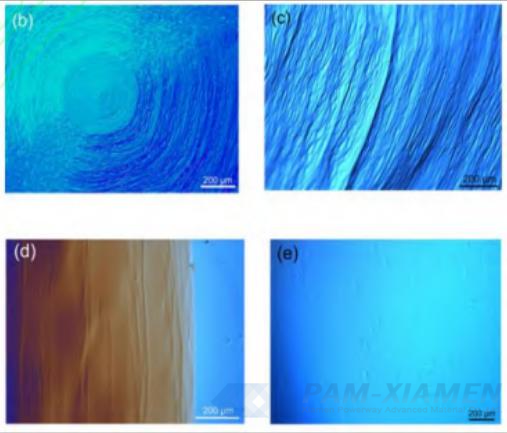

On the surface of SiC crystals grown by PVT method, spiral step growth characteristics can be clearly observed through optical microscopy, especially in the region near small planes, as shown in Fig. 1. Usually, the closer it is to a small flat area, the wider the width of the plane between its steps. However, as it moves away from the small flat area, the width of the steps gradually decreases or even disappears, which is mainly related to the angle between the tangent lines at different positions and the small plane. During the growth process of silicon carbide crystals, the growth steps formed on the surface of the seed crystals help maintain the nucleation and development of a single crystal form.

Fig. 1 Optical image of N doped 4H SiC surface

Guo et al. observed that although there may be a phase transition behavior during crystal growth, the small planar region consistently maintains a single crystal growth of 4H SiC, due to the step growth mode maintained throughout the region. The formation of surface steps can promote the nucleation and growth of gas-phase atoms along the steps or kinks, strictly inheriting the existing stacking information of the growth steps, and thus easily maintaining single crystal growth. In addition to providing growth steps, the width of the plane between the steps is also a key factor affecting the stable growth of the crystal form.

Liu et al. pointed out that when the width of the plane between the growth steps is smaller than the diffusion distance of gas-phase atoms, the gas-phase atoms smoothly enter the step or twist through adsorption and diffusion processes and inherit the stacking order of the inherent crystal form, in order to achieve the goal of stable crystal form. On the contrary, when the atomic diffusion distance is much smaller than the plane width, gas phase atoms are prone to aggregation and form two-dimensional nucleation on the plane, resulting in 15R or 6H polytype inclusions. It can be inferred that the prerequisite for maintaining the growth of a single crystal form of silicon carbide is the formation of surface steps, and the key lies in controlling the plane width between the steps. The use of off-axis seed crystals and the introduction of doping can effectively reduce the plane width between steps, suppress step aggregation behavior, and help achieve stable crystal growth.

2. Influence of Doping Types on Stability of 4H-SiC Crystal Structure

It is usually necessary to prepare SiC single crystal substrates with low resistivity in order to reduce power loss caused by parasitic substrates and contact resistance, and to ensure the reliability of SiC devices. Nitrogen (N) doping as a shallow donor impurity can effectively improve the electrical properties of n-type SiC substrates by occupying the C lattice. Although the theoretical nitrogen doping concentration can reach 5×1020 cm-3, corresponding to a crystal resistivity of 0.005 Ω·cm, the current commercial n-type 4H SiC single crystal substrates mainly have a resistivity range of 0.015~0.025 Ω·cm, corresponding to N doping concentration of 6×1018~1.5×1019 cm-3. This is because heavy doping (≥ 1020 atoms/cm3) can generate significant stacking faults, which in turn alter the crystal structure and generate various electron capture defects, and even lead to 3C polytype inclusions. In addition to improving the conductivity of SiC substrates, N doping has also been proven to be useful for stabilizing the growth of 4H SiC crystal forms.

Nishizawa et al. investigated the effect of N doping on the stability of 4H-SiC crystal form using density functional theory (DFT). The results indicate that doping can significantly expand the stacking energy difference between different crystal forms, and under N doping, the stacking energy difference on the C plane (E6H-E4H) and (E3C-E4H) is much greater than 0, indicating that the 4H-SiC crystal form will preferentially nucleate and grow. Schmitt et al. provided three possible explanations for the mechanism of N-doped stable 4H crystal structure:

1) N doping promotes the increase of C-containing components in the gas phase at the front of the growth interface and reduces the Si/C ratio by occupying the C lattice on the SiC lattice;

2) The reaction between nitrogen and solid carbon forms C2N2 and further enhances the transport capacity of C;

3) A higher nitrogen content in the gas phase helps to suppress step aggregation and reduce the plane width between macroscopic steps.

It can be seen that N doping indeed contributes to the stable growth of 4H SiC crystal form, and the doping effect is also related to the growth temperature. But the control of doping concentration is also crucial, otherwise it will lead to an increase in dislocation density within the crystal and induce the generation of 3C SiC multi type inclusions. Therefore, when selecting doping concentration, it is necessary to balance the relationship between crystal stability and defect density. Rost et al. pointed out that when the doping concentration is greater than 2×1019cm-3, double Shockley stacking faults will occur in the 4H SiC crystal form. It is recommended that the doping concentration be lower than 2×1019 cm-3.

On the contrary, for Al doped systems, 4H SiC tends to grow more on the seed Si surface. This indicates that the selection of seed crystal polarity needs to match the doping type. In addition to the N and Al doping mentioned above, Ce doping has also been proven to have a positive effect on stabilizing the 4H SiC crystal structure.

Since Itoh et al. first proposed in 1994 that Ce doping may help stabilize the 4H SiC crystal structure, related research results have been reported successively. In 2010, Tymicki et al. introduced Ce doping into 4H SiC crystals grown by PVT method, with CeO2 as the cerium source. The results indicate that Ce doping can not only promote the stable growth of 4H SiC crystal form, but also suppress the corrosion on the back of the seed crystal and improve the single crystal yield. Furthermore, Racka et al. used CeSi2 as a cerium source to stably grow 4H SiC crystals on the 6H SiC crystal plane, and explained the main differences between the two cerium sources (CeO2 and CeSi2) during the growth process. That is, compared to CeO2, using CeSi2 as a cerium source under the same preparation conditions helps to obtain silicon carbide crystals with lower electrical resistivity. Unfortunately, none of them have provided a reason for Ce doping to suppress multi type inclusion defects. In 2022, Racka Szmidt et al. provided a possible explanation, pointing out that Ce in the gas phase can enhance the ability of N to enter the SiC lattice, thereby increasing the C/Si ratio in the gas phase components at the front of the growth interface. This is obviously beneficial for stabilizing the 4H SiC crystal form and the optimal doping concentration is 0.5 wt%. If the doping concentration is further increased (1 wt%), it will instead induce polymorphic inclusions.

3. Influence of Other Factors on the Polytypic Stability of 4H-SiC

In addition to the various factors mentioned above, parameters such as crystal growth rate, growth pressure, depressurization rate, and interface front supersaturation also affect the stability of the 4H-SiC crystal structure to varying degrees. Kakimoto et al. conducted a global simulation of the initial nucleation stage of 4H-SiC grown by PVT method based on classical thermodynamic nucleation theory. It was found that the difference in free energy required for nucleation of 4H and 6H SiC crystal forms is positively correlated with growth pressure. Increasing the growth pressure can increase the difference in nucleation energy between the two crystal forms, thereby achieving the growth of a single 4H SiC crystal form. However, excessive pressure clearly hinders crystal growth.

Furthermore, although the supersaturation required for 4H-SiC crystal growth is relatively high, it is not necessarily better to have a higher supersaturation. Yang et al. pointed out that excessive supersaturation during the growth process of 4H-SiC crystal forms can actually induce polytype inclusions in 6H and 15R SiC, especially at the crystal edges. This is because the difference in nucleation free energy between different crystal forms is minimal at the edge of the seed crystal, and lower supersaturation helps to increase the difference in nucleation energy between 4H and 6H SiC crystal forms, thereby stabilizing the growth of 4H SiC.

The two-dimensional nucleation mechanism can be used to explain the reasons for the formation of multi-type inclusion defects caused by excessive supersaturation. When a high degree of supersaturation is formed at the front of the growth interface, the gas-phase material adsorbed on the growth plane does not have time to migrate to the step or twist, causing mutual aggregation between atoms and further nucleation and growth, forming isolated islands and inducing multi-type inclusions. This indirectly indicates that a too fast growth rate is clearly detrimental to the preparation of a single SiC crystal form.

Overall, the 4H-SiC crystal structure tends to grow in the following environment: using the off-axis 4H SiC seed crystal C surface as the growth surface, adjusting the cavity pressure and growth temperature to form a higher C/Si ratio and greater supersaturation at the front of the growth interface. At the same time, cerium and nitrogen doped elements are introduced into the polycrystalline powder and gas-phase components respectively, and the stability of the temperature and airflow fields near the growth interface is maintained as much as possible throughout the entire growth cycle. In order to gain a deeper understanding of the factors and response mechanisms that induce multi type inclusion defects, further discussion and analysis were conducted on the main key parameters from thermodynamic and kinetic perspectives.

For more information, please contact us email at victorchan@powerwaywafer.com and powerwaymaterial@gmail.com.