GaAs (arseniuro de galio) Obleas

As a leading GaAs substrate supplier, PAM-XIAMEN manufactures Epi-ready GaAs(Gallium Arsenide) Wafer Substrate including semi-conducting n type, semi-conductor C doped and p type with prime grade and dummy grade. The GaAs substrate resistivity depends on dopants, Si doped or Zn doped is (0.001~0.009) ohm.cm, C doped one is >=1E7 ohm.cm. The GaAs wafer crystal orientation should be (100) and (111). For (100) orientation, it can be 2°/6°/15° off. The EPD of GaAs wafer normally is <5000/cm2 for LED or <500/cm2 for LD or microelectronics.

- Descripción

Descripción del Producto

(Arseniuro de galio) oblea de GaAs

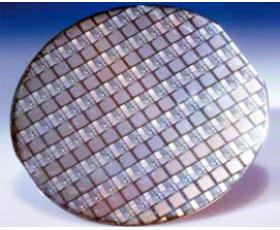

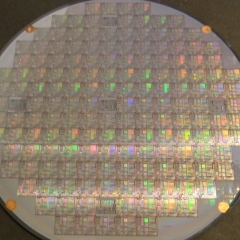

PAM-XIAMEN desarrolla y fabrica sustratos semiconductores compuestos: cristal y obleas de arseniuro de galio. Utilizamos tecnología avanzada de crecimiento de cristales, congelación de gradiente vertical (VGF) y proceso de fabricación de obleas de GaAs, establecimos una línea de producción desde crecimiento de cristales, corte, trituración hasta procesamiento de pulido y construimos una sala limpia de clase 100 para limpieza y empaque de obleas de GaAs. Nuestras obleas de GaAs incluyen lingotes/obleas de 2~6 pulgadas para aplicaciones de LED, LD y microelectrónica. Siempre estamos dedicados a mejorar la calidad de los sustratos de obleas de GaAs actuales y desarrollar sustratos de gran tamaño. El tamaño de la oblea de GaAs que se ofrece es de 2”, 3”, 4” y 6”, y el grosor debe ser de 220-700 um. Además, el precio de la oblea de GaAs que ofrecemos es competitivo.

1. Especificaciones de la oblea de GaAs

1.1 (GaAs)Arseniuro de galioObleas para aplicaciones LED

| Artículo | Especificaciones | Observaciones |

| Tipo de conducción | SC / de tipo n | SC / p de tipo con Zn droga Disponible |

| Método de crecimiento | VGF | |

| dopante | Silicio | Zn disponible |

| oblea Diamter | 2, 3 y 4 pulgadas | Lingote o como de corte availalbe |

| cristal Orientación | (100) 2 °/ 6 ° / 15 ° fuera (110) | Otro desorientación disponibles |

| DE | EJ o US | |

| concentración de portadores | (0,4 ~ 2,5) E18 / cm3 | |

| Resistividad a temperatura ambiente | (1,5 ~ 9) E-3 Ohm.cm | |

| Movilidad | 1500 ~ 3000cm2 / V.seg | |

| Densidad de grabado Pit | <5,000 / cm2 | |

| Marcado láser | a pedido | |

| Acabado de la superficie | P / E o P / P | |

| Espesor | 220 ~ 450um | |

| Listo epitaxia | Sí | |

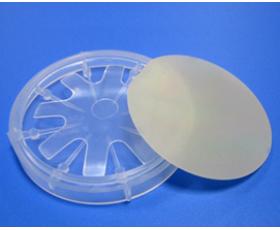

| Paquete | recipiente de rebanada única o casete | |

1,2 (GaAs)Arseniuro de galioObleas para aplicaciones LD

| Artículo | Especificaciones | Observaciones |

| Tipo de conducción | SC / de tipo n | |

| Método de crecimiento | VGF | |

| dopante | Silicio | |

| oblea Diamter | 2, 3 y 4 pulgadas | Lingote o como corte disponibles |

| cristal Orientación | (100) 2 °/ 6 ° / 15 ° fuera (110) | Otro desorientación disponibles |

| DE | EJ o US | |

| concentración de portadores | (0,4 ~ 2,5) E18 / cm3 | |

| Resistividad a temperatura ambiente | (1,5 ~ 9) E-3 Ohm.cm | |

| Movilidad | 1500 ~ 3000 cm2 / V.seg | |

| Densidad de grabado Pit | <500 / cm2 | |

| Marcado láser | a pedido | |

| Acabado de la superficie | P / E o P / P | |

| Espesor | 220 ~ 350um | |

| Listo epitaxia | Sí | |

| Paquete | recipiente de rebanada única o casete | |

1,3 (GaAs)Arseniuro de galioObleas, semi-aislante para aplicaciones de microelectrónica

| Artículo | Especificaciones | Observaciones |

| Tipo de conducción | Aislante | |

| Método de crecimiento | VGF | |

| dopante | C doped | |

| oblea Diamter | 2, 3 y 4 pulgadas | Lingote disponible |

| cristal Orientación | (100)+/- 0,5° | |

| DE | EJ, de Estados Unidos o muesca | |

| concentración de portadores | n / a | |

| Resistividad a temperatura ambiente | > 1E7 Ohm.cm | |

| Movilidad | > 5000 cm2 / V.seg | |

| Densidad de grabado Pit | <8,000 / cm2 | |

| Marcado láser | a pedido | |

| Acabado de la superficie | PÁGINAS | |

| Espesor | 350 ~ 675um | |

| Listo epitaxia | Sí | |

| Paquete | recipiente de rebanada única o casete | |

1,4 6″ (150 mm) (GaAs)Arseniuro de galioObleas, semi-aislante para aplicaciones de microelectrónica

| Artículo | Especificaciones | Observaciones |

| Tipo de conducción | Semiaislante | – |

| Método crecer | VGF | – |

| dopante | C doped | – |

| Tipo | N | – |

| Diamater (mm) | 150 ± 0.25 | – |

| Orientación | (100)0°±3,0° | – |

| muesca de orientación | 〔010〕±2° | – |

| NOTCH Deepth (mm) | (1-1,25)mm 89°-95° | – |

| concentración de portadores | por favor consulte a nuestro equipo de ventas | – |

| Resistividad (ohm.cm) | >1.0×107 | – |

| Movilidad (cm2 / vs) | por favor consulte a nuestro equipo de ventas | – |

| Dislocación | por favor consulte a nuestro equipo de ventas | – |

| Espesor (m) | 675 ± 25 | – |

| Exclusión de última generación para el arco y la deformación (mm) | por favor consulte a nuestro equipo de ventas | – |

| Bow (m) | por favor consulte a nuestro equipo de ventas | – |

| Warp (m) | ≤20.0 | – |

| TTV (m) | ≤10.0 | – |

| TIR (m) | ≤10.0 | – |

| LFPD (m) | por favor consulte a nuestro equipo de ventas | – |

| Pulido | P / P Epi-Ready | – |

1,5 2″(50,8 mm) LT-GaAs (Baja Temperatura arseniuro de galio-Grown) Especificaciones de la oblea

| Artículo | Especificaciones |

| Tipo de conducción | Semiaislante |

| Método crecer | VGF |

| dopante | Sub:C doped / Epi:Undoped |

| Tipo | N |

| Diamater (mm) | 150 ± 0.25 |

| Orientación | (100)0°±3,0° |

| muesca de orientación | 〔010〕±2° |

| NOTCH Deepth (mm) | (1-1,25)mm 89°-95° |

| concentración de portadores | por favor consulte a nuestro equipo de ventas |

| Resistividad (ohm.cm) | >1,0×107 o 0,8-9 x10-3 |

| Movilidad (cm2 / vs) | por favor consulte a nuestro equipo de ventas |

| Dislocación | por favor consulte a nuestro equipo de ventas |

| Espesor (m) | 675 ± 25 |

| Exclusión de última generación para el arco y la deformación (mm) | por favor consulte a nuestro equipo de ventas |

| Bow (m) | por favor consulte a nuestro equipo de ventas |

| Warp (m) | ≤20.0 |

| TTV (m) | ≤10.0 |

| TIR (m) | ≤10.0 |

| LFPD (m) | por favor consulte a nuestro equipo de ventas |

| Pulido | P / P Epi-Ready |

2. Mercado y aplicación de obleas de GaAs

El arseniuro de galio es un importante material semiconductor. Pertenece al grupo III-V de semiconductores compuestos y estructura de red cristalina de blenda de zinc, con una constante de red de 5,65 × 10-10 m, un punto de fusión de 1237 °C y una banda prohibida de 1,4 electronvoltios. El arseniuro de galio se puede convertir en materiales semiaislantes de alta resistencia, que se pueden usar para fabricar sustratos de circuitos integrados, detectores de infrarrojos, detectores de fotones gamma, etc. Debido a que su movilidad de electrones es de 5 a 6 veces mayor que la del silicio, el sustrato SI GaAs tiene Se ha utilizado de manera importante en la fabricación de dispositivos de microondas y circuitos digitales de alta velocidad. Los dispositivos semiconductores fabricados con arseniuro de galio tienen las ventajas de alta frecuencia, alta temperatura, rendimiento a baja temperatura, bajo nivel de ruido y fuerte resistencia a la radiación, lo que hace que se amplíe el mercado de sustratos de GaAs.

3. El certificado de prueba de la oblea de GaAs puede incluir el siguiente análisis si es necesario:

1/Rugosidad de la superficie del arseniuro de galio, incluidos el anverso y el reverso (nanómetros).

2/Concentración de dopaje de arseniuro de galio (cm-3)

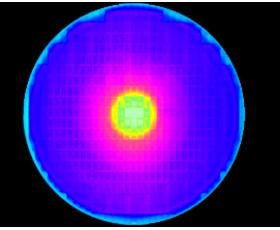

3/EPD de Arseniuro de Galio (cm-2)

4/Movilidad de Galio Arsendie (V.sec)

5/Análisis de difracción de rayos X (curvas oscilantes) de arseniuro de galio: curva de reflexión de difracción de ancho medio

6/Fotoluminiscencia a baja temperatura (espectros de emisión en el rango de 0,7-1,0 μm) de arseniuro de galio: la fracción de fotoluminiscencia de excitón en el espectro de emisión del rango cercano al IR a una temperatura de 4K o 5 K y una densidad de excitación óptica de 1W/cm2

7/Tasa de transmisión o coeficiente de absorción: por un momento, podemos medir el coeficiente de absorción del GaAs monocristalino sin dopar a 1064 nm: <0,6423 cm-1, y esto corresponde a una transmisión mínima del 33,2 % para un blanco de exactamente 6,5 mm de espesor a 1064 nm.

Remark:

The Chinese government has announced new limits on the exportation of Gallium materials (such as GaAs, GaN, Ga2O3, GaP, InGaAs, and GaSb) and Germanium materials used to make semiconductor chips. Starting from August 1, 2023, exporting these materials is only allowed if we obtains a license from the Chinese Ministry of Commerce. Hope for your understanding and cooperation!