PAM-XIAMEN can supply single crystal AlN substrate, additional sepcifications please see: https://www.powerwaywafer.com/aln-substrate.html.

The AlN (aluminum nitride) crystal structure has hexagonal wurtzite (α- Phase) and cubic sphalerite (β- phase), and the hexagonal wurtzite structure is a stable structure, as shown in Fig. 1. AlN belongs to direct bandgap electronic semiconductors with a bandgap width of 6.2 eV. In recent decades, researchers from various countries have been committed to in-depth research on the growth of AlN single crystals and have developed various growth process methods, such as hydride vapor phase epitaxy (HVPE), metal organic chemical vapor deposition (MOCVD), molecular beam epitaxy (MBE), atomic layer deposition (ALD), and physical vapor transport (PVT).

Fig. 1: AlN crystal structure (a) hexagonal wurtzite structure and (b) bonding type

Among them, PVT is widely recognized as the only method for growing high-quality AlN single crystals in bulk form. It has the characteristics of fast growth rate, good crystal integrity, and high safety, and has always been a research hotspot and difficulty in the growth of AlN single crystals. There are three important growth strategies for the growth of AlN single crystal PVT:

1) Spontaneous nucleation and growth;

2) Heteroepitaxial growthon 4H -/6H SiC substrate;

3) Homogeneous epitaxial growth.

Among them, the homogeneous epitaxial growth method can use small-sized aluminum nitride crystals obtained through spontaneous nucleation growth as seed crystals for crystal expansion growth. Due to its absence of lattice mismatch effects, it can maintain or even improve the quality of epitaxial crystals, while achieving the advantage of expanding crystal size.

1. AlN Growth Habit Surface

In the AIN cell, the (0001), [10-10], [-12-10], and [10-11] planes are relatively densely packed crystal planes in the lattice, with corresponding plane network densities of 1.15/a2, 1.25/a2, 144/a2, and 1.65/a2. These crystal planes can all serve as growth planes for AlN crystals. The actual growth of AIN crystals depends on the temperature and supersaturation of the atmosphere at which the crystal is grown. The final crystal morphology is closely related to the environmental phase and crystal structure, and exhibits a specific crystal morphology. This phenomenon is called crystal growth habit, and the corresponding growth crystal plane is the growth habit plane.

According to Lewis’s research results, the surface of the crystal obtains favorable twisting positions for crystal growth through two-dimensional nucleation, which is related to its interface energy. In the case of high supersaturation, crystal planes with high interface energy and crystal planes with low interface energy can freely nucleate and grow. Crystal growth can be achieved without following specific growth habits, and the grown crystals do not reflect specific crystal shapes. In the case of low supersaturation, crystal planes with high interfacial energy are more likely to form two-dimensional nuclei and receive preferential growth than those with low interfacial energy. The two-dimensional nucleation of crystal planes with low interfacial energy is often suppressed, and the growth rate of crystal planes lags behind those with high interfacial energy. In this case, the result of crystal growth is that the crystal has a specific crystal shape.

2. The Relationship Between AlN Crystal Habits and Growth Temperature

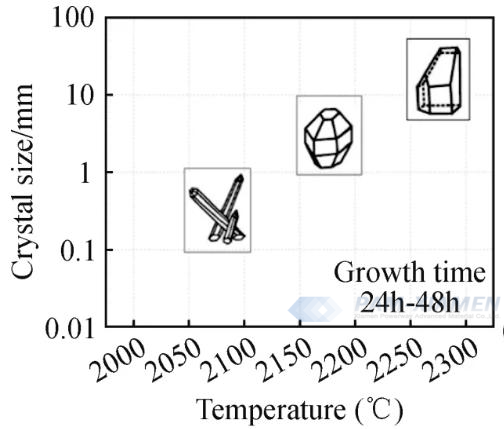

Numerous spontaneous nucleation growth experiments have shown that when the growth temperature is low, the spontaneously grown crystals grow in a spiral needle like shape, with a growth rate several orders of magnitude higher in the c-direction than in other directions; When the growth temperature is between 2050~2100 ℃, the macroscopic morphology of crystal growth changes from needle shaped to typical hexagonal prism shaped; When the growth temperature increases to 2150-2200 ℃, the crystal exhibits equiaxed growth. However, when the growth temperature further increases to 2250-2300 ℃, the macroscopic morphology of the crystal shows an irregular wedge shape, as shown in Fig. 2.

Fig. 2 Relationship between AlN crystal habits and growth temperature

For more information, please contact us email at victorchan@powerwaywafer.com and powerwaymaterial@gmail.com.