With the driving force of Automotive and Industrial electronics, the strong growth of the silicon carbide (SiC) power semiconductor market is expected to approach $10 billion in the coming years. At the same time, many industry participants have announced corresponding expansion plans to quickly seize market share. The cooperation and integration among major industry participants are reshaping the supply chain of silicon carbide.

As a member of industry participants, PAM-XIAMEN always aim to supply you high-performance power SiC wafers, more wafer specifications please visit: https://www.powerwaywafer.com/sic-wafer

1. 2022~2028 SiC Wafer Market Growth Rate

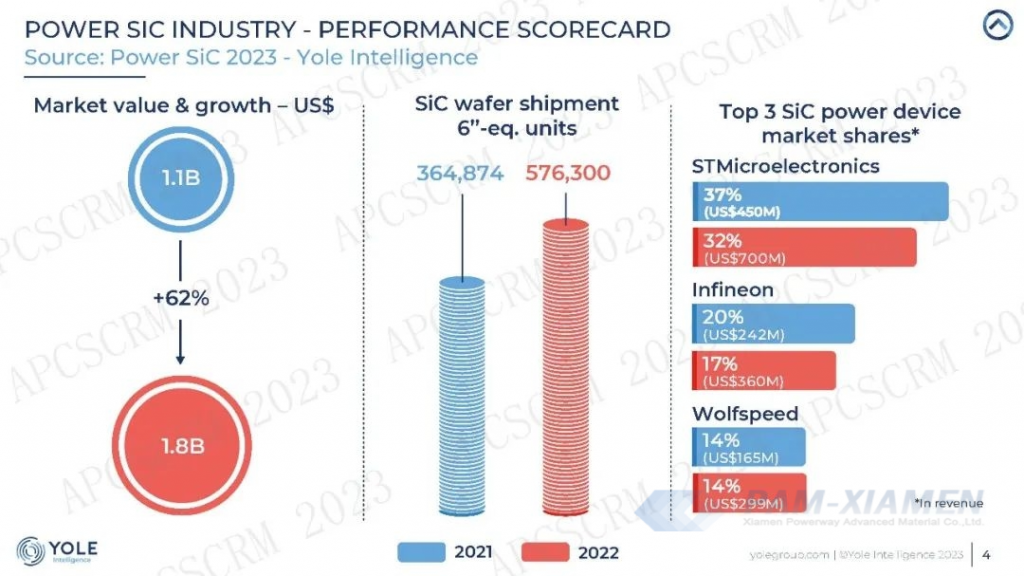

According to Yole’s Power SiC 2023 report, the SiC power semiconductor market has grown from $1.1 billion in 2021 to $1.8 billion in 2022, with an annual growth rate of 62%. The shipment volume of silicon carbide wafers (equivalent to 6 inches) has increased from 360000 pieces to 570000 pieces.

Fig.1 Power SiC industry – performance scorecard

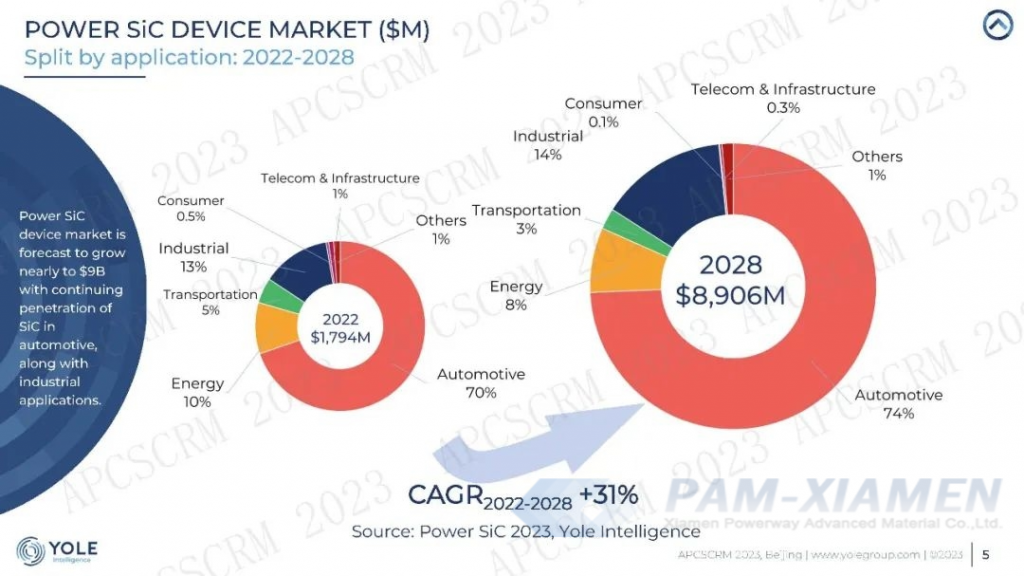

Yole estimates that the SiC power semiconductor market is expected to grow from $17.9 billion in 2022 to $89 billion in 2028, with a compound annual growth rate (CAGR) of 31%. Among them, automotive electronics and industrial electronics contribute over 85%.

Fig. 2 Power SiC device market

2. Power SiC Wafer Cost from 2022 to 2028

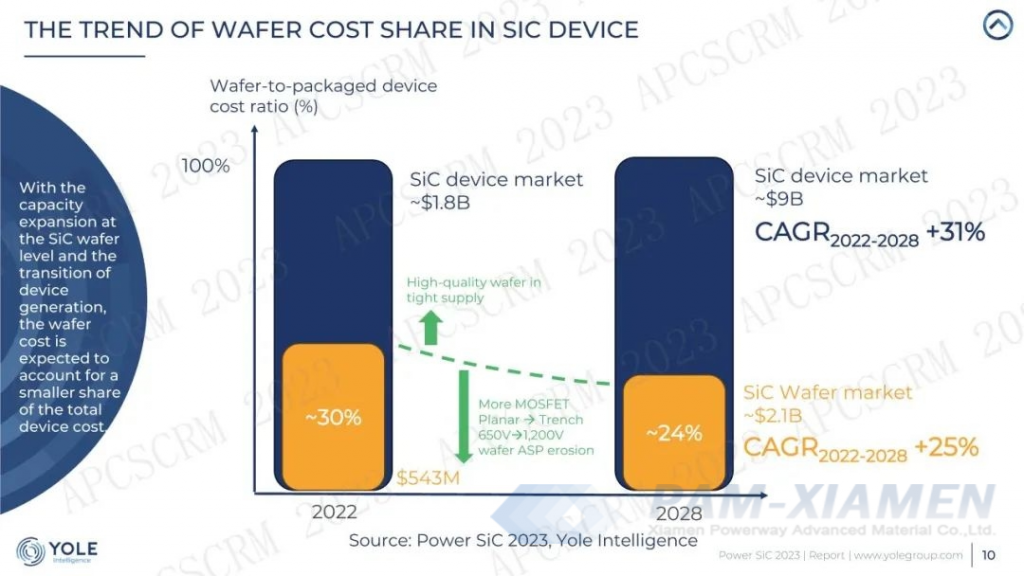

With the continuous increase in SiC wafer production capacity, the proportion of wafer cost to total device cost will continue to decrease. Yole predicts that the cost proportion of SiC wafers will decrease from 30% in 2022 to 24% in 2028, thanks to the improvement in SiC wafer production yield and the reduction in MOSFET device volume, such as more planar designs shifting to trench designs.

Fig. 3 Trend of wafer cost share in SiC device

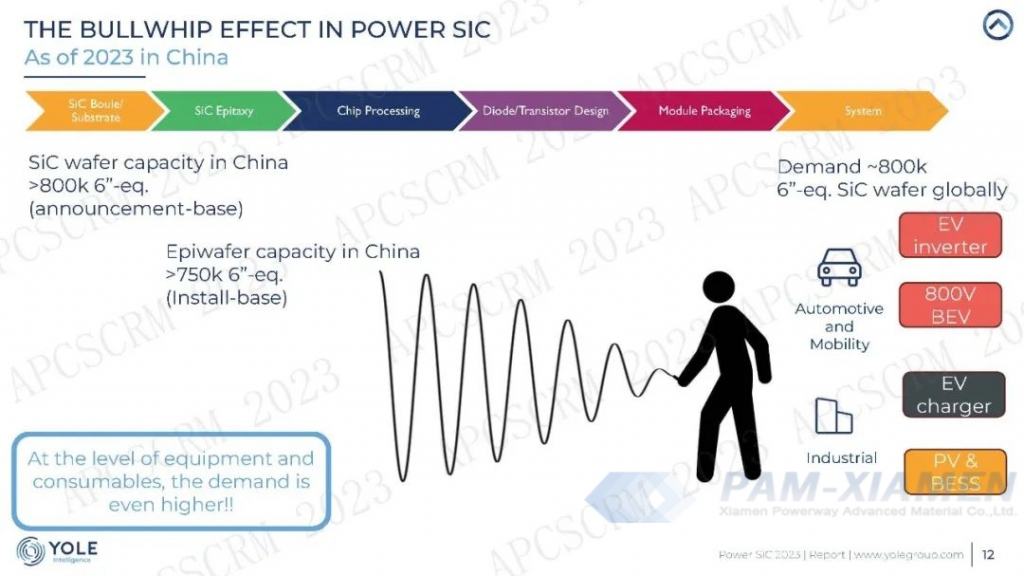

The Bullwhip effect refers to the amplification phenomenon that occurs when the demand information of downstream enterprises in the industrial chain is transmitted to upstream enterprises. From the perspective of SiC wafer production capacity layout, there may be overcapacity in the future, and changes in downstream consumer market demand are likely to lead to significant fluctuations in SiC wafer inventory.

Fig. 4 The Bullwhip effect in power SiC

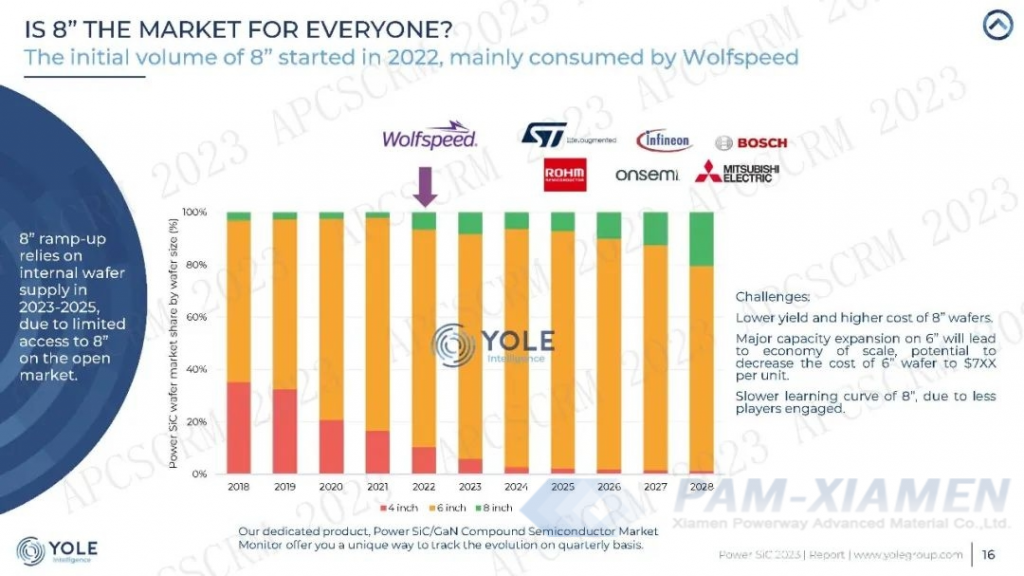

3. Market Analysis of 8inch SiC Wafers

The proportion of 8-inch SiC wafers is currently not high, which is closely related to the low yield and high cost of their production process. The expansion of production capacity for 6-inch silicon carbide wafers will bring economies of scale dividends, potentially lowering their costs to $700 per wafer.

Fig. 5 Power SiC wafer market share by wafer size

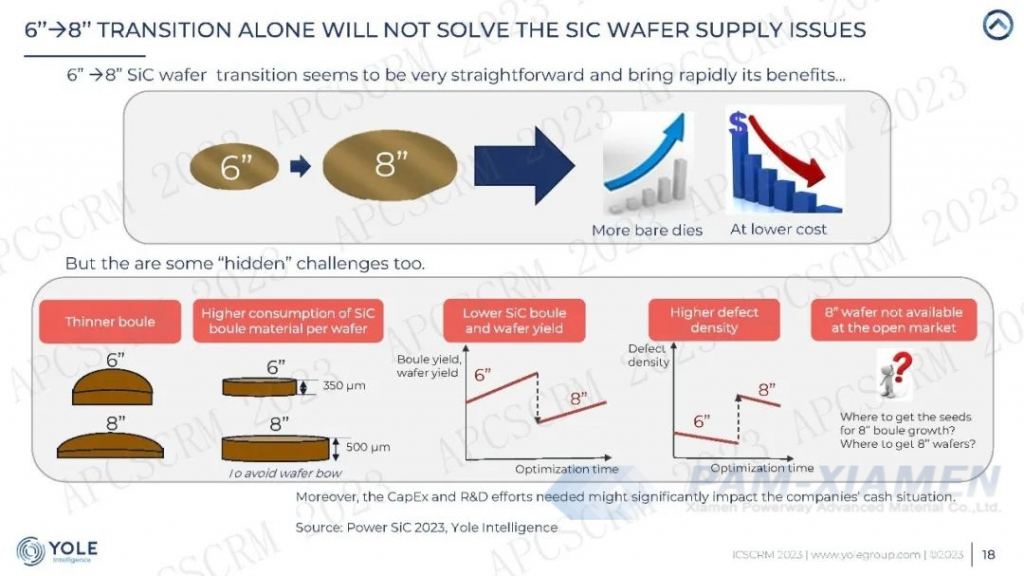

The conversion of SiC wafers from 6 inches to 8 inches may seem to significantly reduce costs and bring rapid benefits, but in reality, there are still many hidden challenges. For example, increasing the thickness of an 8-inch wafer will reduce the utilization rate of the ingot; The low yield and high defect density of 8-inch SiC wafers pose obstacles to their large-scale application.

Fig. 6 Issues for transition of SiC wafer from 6 inches to 8 inches

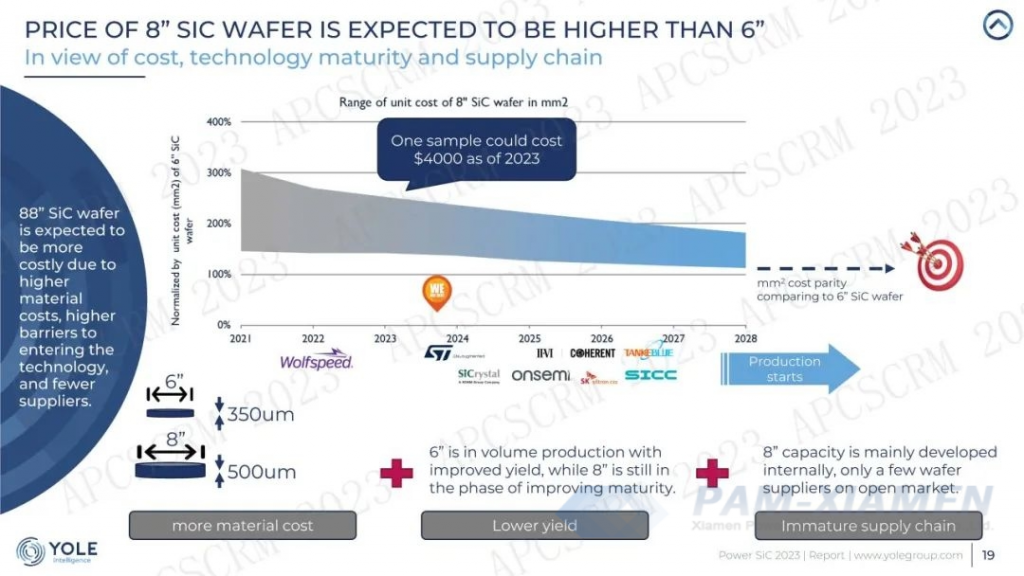

Compared to 6-inch SiC wafers, 8-inch SiC wafers will not have any short-term price advantages, which are closely related to cost control (more expensive), technological maturity (lower yield), and market openness (more closed).

Fig. 7 Price of 8 inch SiC Wafer

For more information, please contact us email at victorchan@powerwaywafer.com and powerwaymaterial@gmail.com.