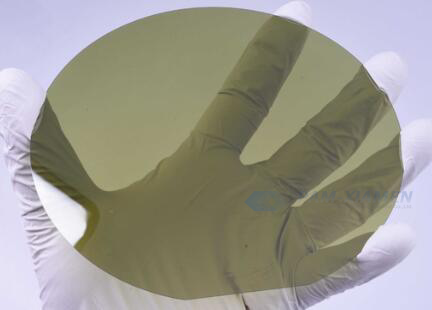

MESFET (Metal-Semiconductor Field Effect Transistor) is a field-effect transistor composed of Schottky barrier gates. SiC microwave MESFET was developed between 1995 and 2002 to replace GaAs microwave field effect transistors (FETs). There are three types of substrate materials used conductive substrate (n+- SiC), high-purity semi insulating substrate (SI SiC), or insulating substrate (sapphire, diamond, or SiCOI materials, etc.) for growing MESFET epi structure. Due to the much lower hole mobility than electron mobility in SiC materials, n-channel MESFET device structures are mostly used in the development of SiC microwave power devices. PAM-XIAMEN can supply SiC MESFET epitaxial wafers, with specific parameters as follows. We grow a p-type buffer layer to achieve isolation and prevent leakage; To ensure a small ohmic contact resistance, the concentration should be as high as possible when epitaxial growth of the contact layer.

1. SiC MESFET Epi-Structure

| Epi Layer | Thickness | Doping Concentration |

| n type contact layer | 200nm | (2~4)×1019cm–3 |

| n type channel | 350~550nm | (1~3 )×1017cm–3 |

| p type buffer | >400nm | 2×1015~1×1017cm–3 |

| n+ or semi-insulating SiC substrate |

2. Why Fabricate MESFET Devices based on 4H-SiC Wafer?

Among the numerous SiC polymer states, 4H-SiC is more competitive in the field of microwave power device manufacturing due to its wider bandgap, higher electron mobility, lower anisotropy, and lower impurity ionization energy (which can achieve higher impurity ionization rate). Theoretical research has shown that for 4H-SiC MESFET devices with the same size, power density and other indicators can be achieved more than 10 times higher than Si or GaAs MESFET by simply increasing the operating voltage.

Moreover, compared to GaAs MESFET, SiC MESFET has other performance advantages:

1) Due to the high input and output impedances, there is no need for internal matching in device applications, and the external matching circuit can also be greatly simplified;

2) For portable mobile communication base stations, their 48V high-voltage DC power supply can directly drive SiC MESFET, eliminating the need for other peripheral circuits including DC-DC converters;

3) The advantage of high thermal conductivity can greatly reduce or even eliminate the need for cooling systems in SiC power devices.

These advantages all indicate that the use of SiC devices can produce devices and devices that are lighter, more flexible, and have higher performance and stability, which is very suitable for mobile communication systems to meet the requirements of small size, light weight, radiation resistance, and high performance. Applying SiC high-frequency power devices to solid-state phased array radar transmission components can achieve higher transmission output power, significantly improve its detection range and resolution ability for stealth targets, and have higher reliability than current traveling wave tubes.

For more information, please contact us email at victorchan@powerwaywafer.com and powerwaymaterial@gmail.com.