Single crystal 3C-SiC substrate can be supplied with specifications as: https://www.powerwaywafer.com/3c-sic-wafer.html.

Silicon carbide (SiC) has excellent properties such as wide bandgap, high breakdown field strength, high saturation electron drift rate, and high thermal conductivity, and has important applications in fields such as new energy vehicles, photovoltaics, and 5G communication. Compared with the widely used 4H-SiC, cubic SiC (3C SiC) has higher carrier mobility (2-4 times), lower interface defect density of states (one order of magnitude lower), and higher electron affinity (3.7 eV). The use of 3C-SiC to prepare field-effect transistors can solve the problem of poor device reliability caused by multiple gate oxygen interface defects. But the progress of 3C-SiC based transistors is slow, mainly due to the lack of single crystal substrates. Previous studies have shown that 3C-SiC is prone to phase transition during growth, and existing growth methods cannot obtain crystals with a single crystal form.

1. Stable Growth of 3C-SiC Grown on 4H-SiC Via TSSG

According to the classical crystal growth theory, for smooth interface crystals, homogeneous two-dimensional nucleation needs to overcome critical potential barriers, with the existence of critical Gibbs free energy or supersaturation, while growth can occur at any small supersaturation. For heterogeneous nucleation, due to the introduction of new solid-solid interface energy, two-dimensional nucleation needs to overcome higher critical potential barriers. Therefore, under the same supersaturation, homogeneous nucleation and growth are significantly better in terms of energy than heterogeneous nucleation and growth, making the latter difficult to occur.

Recently, a research team has proposed the academic idea of regulating the solid-liquid interface energy to prioritize nucleation and growth on heterogeneous seed crystals compared to homogeneous seed crystals. Mainly including:

1) The lattice mismatch between the 3C (111)-melt and 4H (0001)-melt surfaces is small, and the solid-solid interface energy is very low;

2) The difference in Gibbs free energy between 4H and 3C bulk phases is relatively small;

3) If the interface energy of 3C (111) – melt is sufficiently low compared to that of 4H (0001) – melt by adjusting the melt composition, the two-dimensional nucleation and subsequent growth of Gibbs free energy are more favorable for the 3C phase.

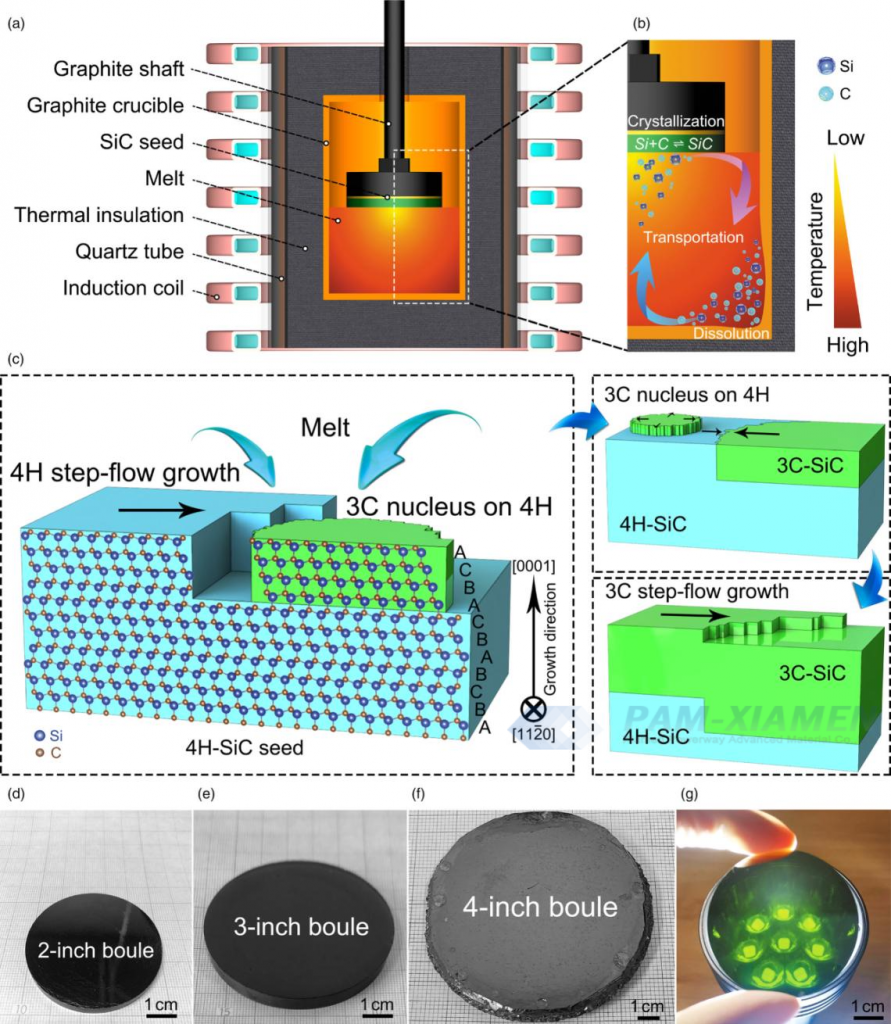

The team independently designed and built testing equipment for surface tension and solid-liquid contact angle of ultra-high temperature melts. The surface tension of different compositions of melts and the contact angle between the melt and 4H-SiC, 3C-SiC were measured at high temperatures, and the variation law of solid-liquid interface energy between 4H-SiC, 3C-SiC and high-temperature melt was obtained, verifying the feasibility of interface energy regulation. The team utilized the high-temperature liquid phase method to achieve a lower Gibbs free energy requirement for 3C-SiC under the same supersaturation conditions, suppressing phase transitions during growth. For the first time internationally, 3C-SiC single crystals with a diameter of 2-4 inches, a thickness of 4-10mm, and a single crystal form were grown, as shown in Fig. 1.

Fig. 1 Heterogeneous nucleation and stable crystal growth of 2-4 inches, 4-10 mm thick 3C-SiC were achieved on 4H-SiC seed crystals using TSSG method

2. Properties of TSSG Grown 3C-SiC Single Crystal

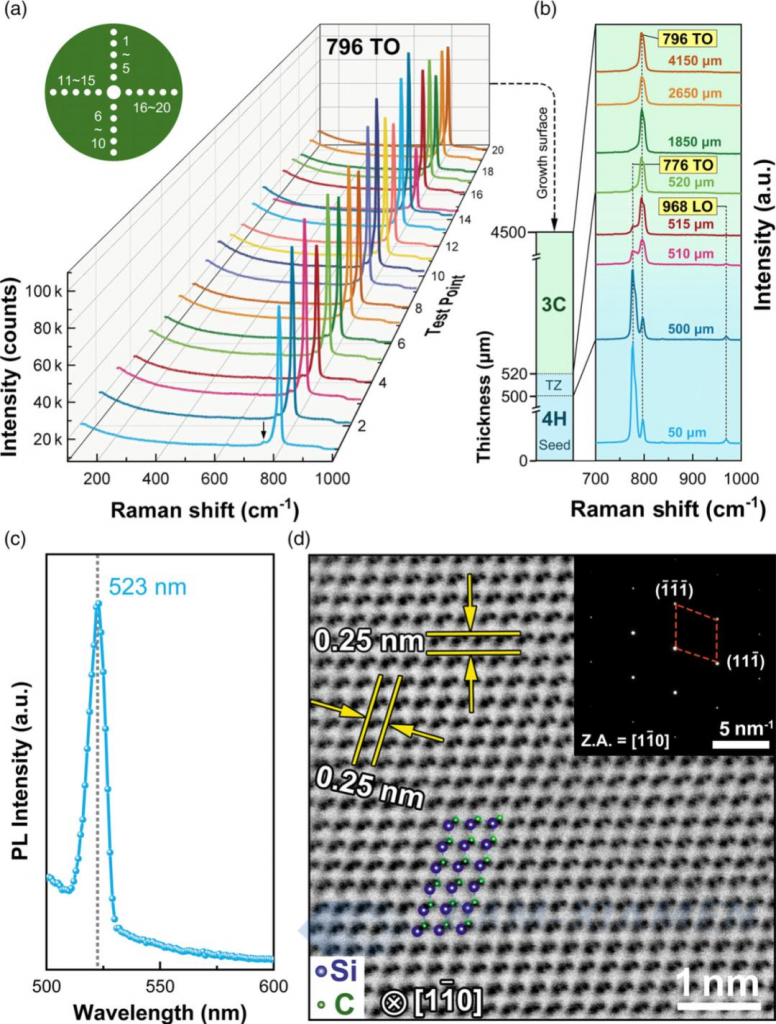

The Raman scattering spectroscopy measurements along the crystal thickness direction indicate that at the beginning of growth, 3C-SiC nucleates and grows on the 4H-SiC seed crystal, with a coexistence zone of less than 20μm. Fig. 2 (a-b) further confirms the above theory. The average half width of the X-ray rocking curve on the (111) growth surface is 30 arcsec, indicating that the grown 3C SiC has high crystal quality. The room temperature resistivity of 3C SiC single crystal is only 0.58 m Ω·cm, which is 1/40 of the commercial 4H-SiC wafer resistivity (15-28 mΩ·cm) and is expected to reduce the energy loss of the device.

Fig. 2 Determination of 3C-SiC crystal structure. a) Randomly select 20 Raman scattering spectra from the (111) growth surface, and the inset shows the distribution of test points on the crystal. b) Raman scattering spectra along the crystal thickness direction. c) Photoluminescence (PL) spectrum measured at 300K. d) High angle annular dark field scanning transmission electron microscopy (HAADF-STEM) image. The illustration shows the selected area electron diffraction (SAED) pattern along the [110] crystal band axis.

The growth of wafer level 3C-SiC single crystals fills the gap at global, making mass production of 3C-SiC crystals possible and providing new opportunities for the development of high-performance power electronic devices. Meanwhile, the mechanism of preferential nucleation and growth on heterogeneous seed crystals compared to homogeneous seed crystals expands the traditional crystal growth theory.

For more information, please contact us email at victorchan@powerwaywafer.com and powerwaymaterial@gmail.com.