Aluminum nitride (AlN) is a widely used III-V group nitride with a hexagonal wurtzite structure in the field of acoustic electronic devices. It has a large direct bandgap (bandgap of 6.2 eV), is compatible with CMOS technology, and has high thermal conductivity. In addition, aluminum nitride thin films have achieved rapid development due to their characteristics such as high surface acoustic wave (SAW) phase velocity and low material temperature coefficient (TCD). However, due to limitations in the application of AlN thin films, their lateral effective electromechanical coupling coefficient is relatively small (≈ 0.5%). In order to improve its electromechanical coupling coefficient while retaining other excellent characteristics, an effective method is to dope it to create new ternary nitrides, which is achieved together with other III nitrides and transition metals. Scandium (Sc) is an IIIB group element and is commonly considered a transition metal. Sc generally exists stably as ScN compounds and has a cubic salt stone structure. Due to the similar size of scandium atoms and Al atoms, it has the stability of transition metals and is currently a hot topic in the research of subgroup elements.

PAM-XIAMEN can supply AlScN thin film materials, more parameters please refer to: https://www.powerwaywafer.com/alscn-template.html.

1. Effect of Sc Doping with Different Concentrations on AlN Crystal Structure

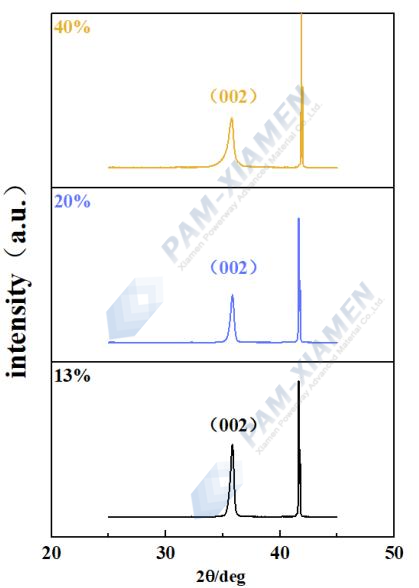

ScxAl1-xN thin films studied were prepared on sapphire substrate using magnetron sputtering method at three concentrations of ScAl alloy targets: 13%, 20%, and 40%. The XRD test results are shown in Fig.1. Through observation, the (002) diffraction peak at each concentration is obvious, and the intensity and half width at half maximum indicate that it has a good C-axis preferred orientation. When the concentration of doped Sc atoms increases, the cell volume increases, the interplanar spacing d of the crystal increases, and the angle θ at the (002) diffraction characteristic peak decreases accordingly. When the concentration of Sc doping increases from 13% to 20%, the increase of 2θ at the diffraction peak (002) is not significant because the doping amount does not change much. When the concentration is increased from 20% to 40%, 2θ at the diffraction peak of (002) is reduced from 35.82 ° to 35.77 °.

As the doping concentration of Sc atoms increases, the trend of crystal cell growth also changes. Because the volume of Sc atoms is larger than that of Al atoms, when Sc enters AlN, it will lead to an increase in the crystal axis a and c directions. However, the growth of crystal cells in the a-axis direction is faster, and their c/a is gradually decreasing. Due to the different coordination modes of w-AlN, ScN, and h-ScN, when Sc enters the w-AlN structure, it competes with Al for N.

Fig. 1 XRD diagram for AlN crystal with different Sc concentrations

2. Sc Doping Concentration Impacts on Performance of AlN

As the Sc doping concentration increases, this competition becomes more intense, leading to structural distortion, softening of the structure, and a decrease in c/a. The softening of the crystal also leads to an increase in its piezoelectric sensitivity. The piezoelectricity produced a huge piezoelectric response 500% times that of AlN when the Sc concentration reached 40%.

In addition, in other research fields related to integrated photonics, this material exhibits excellent performance in both optical and pyroelectric properties.

For more information, please contact us email at victorchan@powerwaywafer.com and powerwaymaterial@gmail.com.