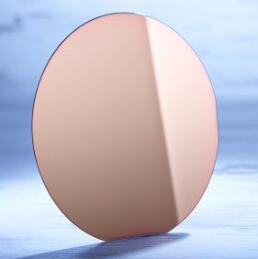

GaAs quantum well VCSEL wafer with an emission wavelength of 808nm is available for optical pumping. VCSEL (Vertical Cavity Surface Emitting Laser) is developed on the basis of gallium arsenide semiconductor materials. The VCSEL fabrication of devices has the advantages of small size, small circular output spot, single longitudinal mode output, low threshold current, low price, and easy integration into a large-area array. Here is the wafer structure of visible wavelength VCSEL material epitaxially-grown on GaAs substrate for your reference, or you can offer PAM-XIAMEN a customized visible wavelength VCSEL material epitaxy structure to evaluate whether it can do or not.

1. 808nm VCSEL Wafer Epi Structure

PAM210706-808VCSEL

|

808 nm VCSEL Epi Structure |

||||||||

| Material | layer Group | Rpts | Mole-fraction (x) | PL (nm) | Thickness (nm) | Dopant | Type | Doping level |

| GaAs | – | – | – | – | 20 | C | – | 3.0E19 |

| AlxGaAs | – | – | – | – | – | – | – | – |

| AlxGaAs | DBR | – | – | – | – | – | – | – |

| AlxGaAs | – | – | – | – | 47 | – | – | – |

| AlxGaAs | – | – | – | – | – | – | – | – |

| AlxGaAs | – | – | – | – | – | – | – | – |

| AlxGaAs | – | – | – | – | – | U/D | – | – |

| AlxGaAs | – | – | 0.3 | – | – | – | – | – |

| AlGaInAs | – | – | – | 793 | – | – | – | – |

| AlxGaAs | – | – | – | – | – | – | – | – |

| AlGaInAs | – | 2 | – | – | 6 | – | – | – |

| AlxGaAs | – | – | – | – | 4 | – | – | – |

| AlxGaAs | – | – | – | – | – | – | – | – |

| AlxGaAs | – | – | – | – | – | – | N | – |

| AlxGaAs | – | – | – | – | – | – | – | – |

| GaAs | 0 | – | – | – | – | Si | – | – |

| Substrate | 4° toward (110) | – | – | – | – | – | ||

2. Why Choose 808nm VCSEL Epiwafer for Optical Pumping?

In the laser, the pump source plays a function of excitation source, and the VCSEL laser wafer with 808nm emission wavelength is the key component of the pump source. The pump source working principle is that use laser diode on 808nm VCSEL laser wafer to pump by injecting current. The working voltage and current make a compatibility with integrated circuit, thereby integrating the threshold single, obtaining a high speed modulated laser output. The requirements of laser for laser performance are uniform optical properties, excellent optical transparency and stable. In a word, the 808nm VCSEL epi wafer is very suitable for the high-power semiconductor pumped solid-state laser.

2.1 Comparison between VCSEL Laser Pump Source and Traditional Laser Pump Source

Through the comparison with the traditional side-emission 808nm laser pump source, VCSEL semiconductor device based on VCSEL wafer has a good wavelength stability. The wavelength temperature coefficient of 808nm VCSEL wafer is 0.07nm/°C, while that of the traditional one is 0.25-0.3nm/°C. In addition, the VCSEL laser wafer has the features of small divergence angle and round beam output. It is beneficial for collimation or focusing, reducing the cost and improving the reliability, simplifying the coupling link. VCSEL with the wafer epitaxial structure from PAM-XIAMEN, meeting the industrial standards, has the advantages of high reliability and wide operating temperature range. Using vcsel laser pump sources is the future trends of high performance solid state lasers and chip solid state lasers.

2.2 Advantages of VCSEL Wafer Epitaxial Structure for Optical Pump

Moreover, a high-efficiency heat dissipation method is required, so the traditional bottom-emitting VCSEL structure is no longer applicable. Tests carried out by PAM-XIAMEN found that the substrate material GaAs has a strong absorption at 808 nm. Therefore, VCSEL wafer at 808nm is more applicable for optical pumping.

The VCSEL chip fabricated on VCSEL wafer has an electro-optical conversion efficiency up to 45%, high reliability, high beam quality, long life, compact structure and low cost. As the core accessory of semiconductor-pumped solid-state lasers, 808nm VCSEL chips have been favored and praised by customers on the market.

3. VCSEL Wafer Application Trend

Focusing on VCSEL industry, there are at least four popular application trends worthy of the VCSEL wafer manufacturers’ attention:

- With the rise of non-invasive medical treatment, the demand for VCSEL wafer in laser medical treatment is increasing day by day.

- The development trend of smart hardware has penetrated into many aspects of the optoelectronic industry, and the smart camera module of GaAs based 3D TOF VCSEL wafer has emerged.

- AI technology has gradually matured. LiDAR is an indispensable part for intelligent driving. The core device of LiDAR is Vehicle-level high power pulse VCSEL.

- With the development of 5G technology, there is a huge market demand for optical communication chips and TO packaged diodes.

With the advancement of VCSEL manufacturing and VCSEL fabrication processes at home and abroad, 808 nm VCSEL wafer arrays are developing in the direction of large size, high peak power, and high power density. VCSEL wafers will also become more and more suitable for use as pump light sources for all-solid-state lasers, research and business fields.

4. FAQ for VCSEL Wafer

Q: May I ask if any information on the optical pumping (pump wavelength, threshold power, operating tempreature) on the 4inch VCSEL epiwafer is available?

A: To obtain specific data for below parameters of optical pumping device based on our 4”size VCSEL wafer, please contact victorchan@powerwaywafer.com:

Oxidation pore size: XX

ITH: XX

Voltage: XX

Power: XX

PCE: XX

Longitudinal cavity length: XX.

More about the VCSEL laser epi wafer, please read:

GaAs Epiwafer with AlGaAs Multilayers for VCSEL Laser Application

For more information, please contact us email at victorchan@powerwaywafer.com and powerwaymaterial@gmail.com.